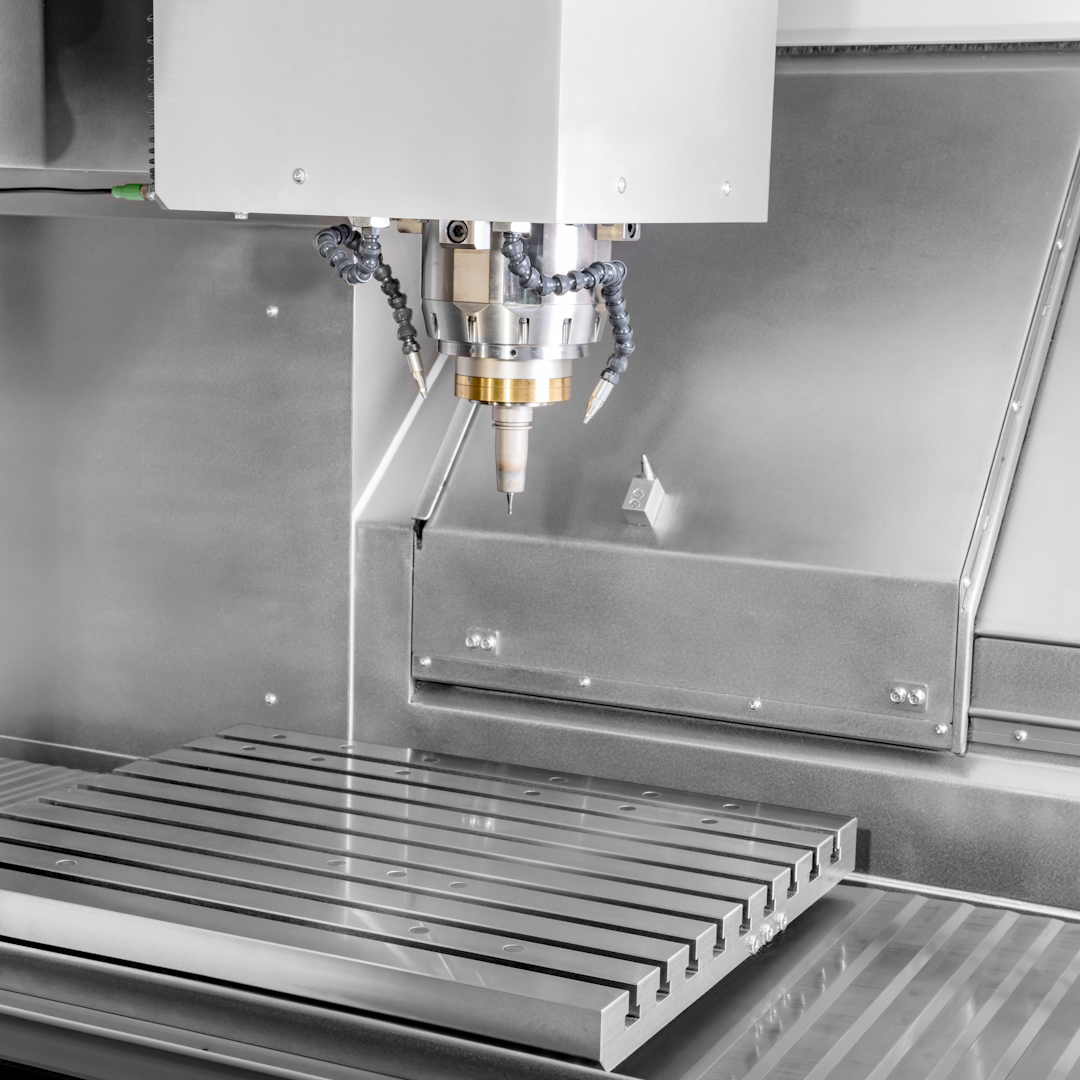

Röders 3-Axis RPT Series

The Röders 3-Axis RPT Series is a compact 3-axis milling, grinding, and measuring centre engineered for maximum precision, exceptional surface quality, and shorter processing times. Featuring PRECITEMP® thermal control and the NANOTOL® guideway concept, it achieves nanometre-level running accuracy and outstanding surface finishes. The Röders 3-Axis RPT Series is ideal for optical applications, high gloss mould tools, and ultrahigh precision milling and jig grinding.

There are two models within the Röders 3-Axis RPT Series: RPT600 and RPT800.

Highlights

- PRECITEMP® thermal control for consistent accuracy in varying temperatures

- NANOTOL® guideways for ultra-smooth motion, rigidity, durability, and no energy consumption (unlike hydrostatics)

- Capable of milling, grinding, and measuring in a single setup

- Ultra stable engineered granite portable gantry machine frame to enhance precision

Share

Technical Specifications

Machining Range

RPT600: 630mm x 530mm x 300mm (X,Y,Z)

RPT800: 840mm x 635mm x 500mm (X,Y,Z)

Table Size

RPT600: 600 mm x 500 mm (X,Y), T‑slots 14 mm

RPT800: 796mm x 596mm (X,Y), T‑slots 14mm

Clamping Unit

RPT600: Erowa UPC / System 3R Dynafix / Parotec Power Grip 160

RPT800: individual solutions possible up to 600mm width

Workpiece Weight

RPT600: Maximum 400kg

RPT800: Maximum 800kg

Feed

RPT600 & RPT800: 0–60,000mm/min

Milling Spindle

Spindle options available from high torque 102Nm or high speed 120,000rpm for a range of applications

Tool Changer

RPT600: 42 or 87 places for HSK E40, optional larger changer available, integrated measuring laser

RPT800: 40 or 84 places for HSK E50, optional larger changer available, integrated measuring laser

Chip Disposal

RPT600 & RPT800: With 2 screws into chip box behind the machine or with additional chip conveyor

Machine Weight & Dimensions

RPT600: ~8.8t and 2200mm x 250mm x 2540mm (W,L,H)

RPT800: ~10.5t and 2400mm x 3000mm x 3175mm (W,L,H)

Explore Other CNC Machines

-

Röders 5-Axis RPT Series

Röders 5-Axis RPT SeriesThe Röders 5-Axis RPT Series is a 5-axis milling, grinding, and measuring centre engineered for maximum precision, exceptional surface quality, and shorter processing times. It's ideal for mould, die, and high-value production applications.

-

Röders 3-Axis RXP Series

Röders 3-Axis RXP SeriesThe Röders 3-Axis RXP Series delivers high-speed, high-precision milling with linear motor drives. The range includes compact models for micromachining and larger machines for heavy-duty, high-speed cutting such as transfer stamping dies.

-

Röders 5-Axis RXP Series

Röders 5-Axis RXP SeriesThe Röders 5-Axis RXP Series are high-speed machining centres engineered for extreme precision, dynamic performance, and superior surface quality. They are ideal for aerospace, mould and die, and high- precision component manufacturing.