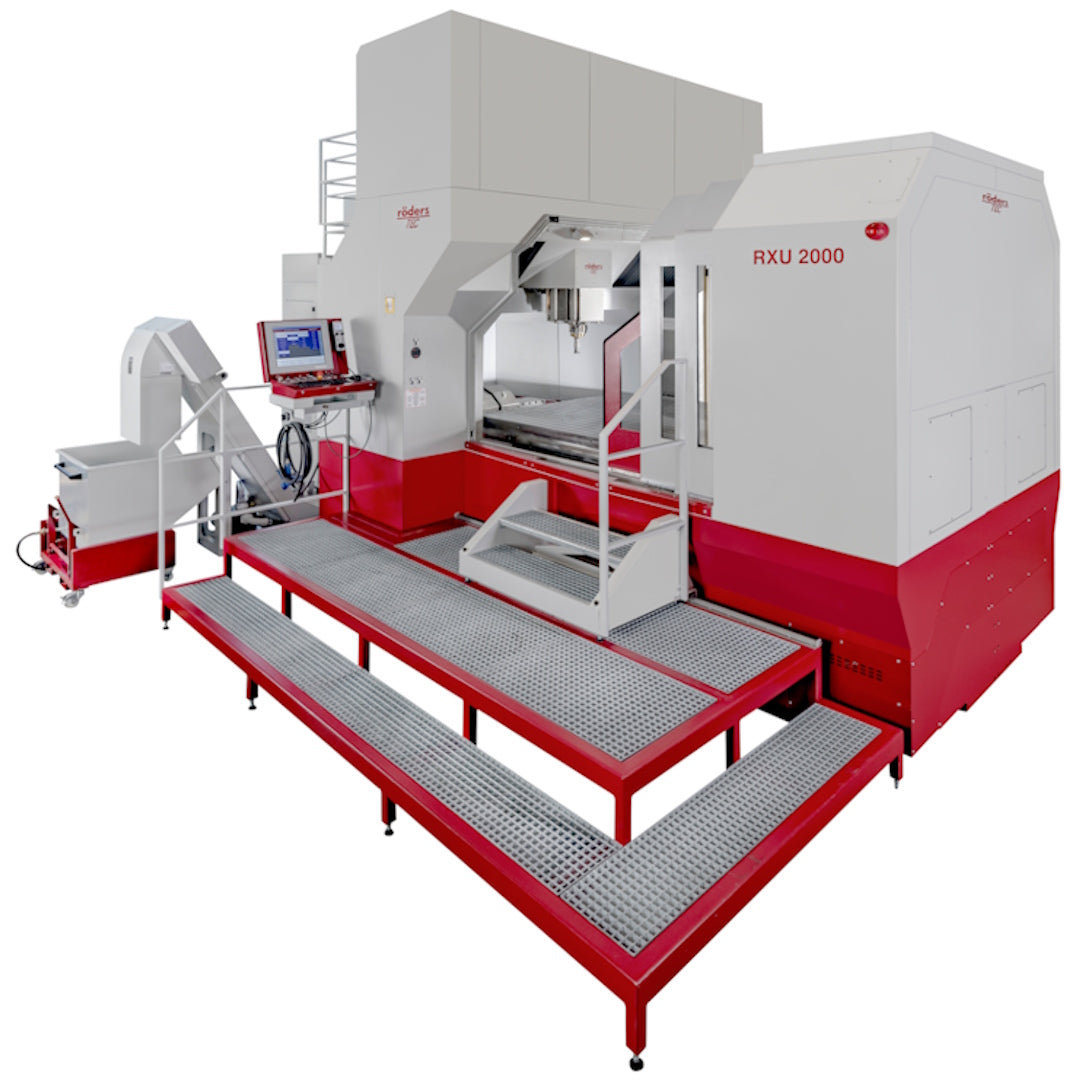

Röders 3-Axis RXU Series

The Röders 3 Axis RXU series delivers high-speed, high-precision machining through Röders’ patented QUADROGUIDE® design, which channels cutting forces via four stiff corner rails into a massive machine bridge for unrivalled rigidity and dynamic performance. Equipped with wear-free zero backlash linear motors, powerful spindles, and rapids and feeds up to 60m/min, they excel in heavy-duty, single-setup operations even with hardened materials. The series includes models tailored to a range of scales and workloads, making them ideal for mould-and-die, aerospace, and large component production.

The Röders 3‑Axis RXU series features 4 configurations: RXU1001, RXU1401, RXU2000, and the RXU2600.

Highlights

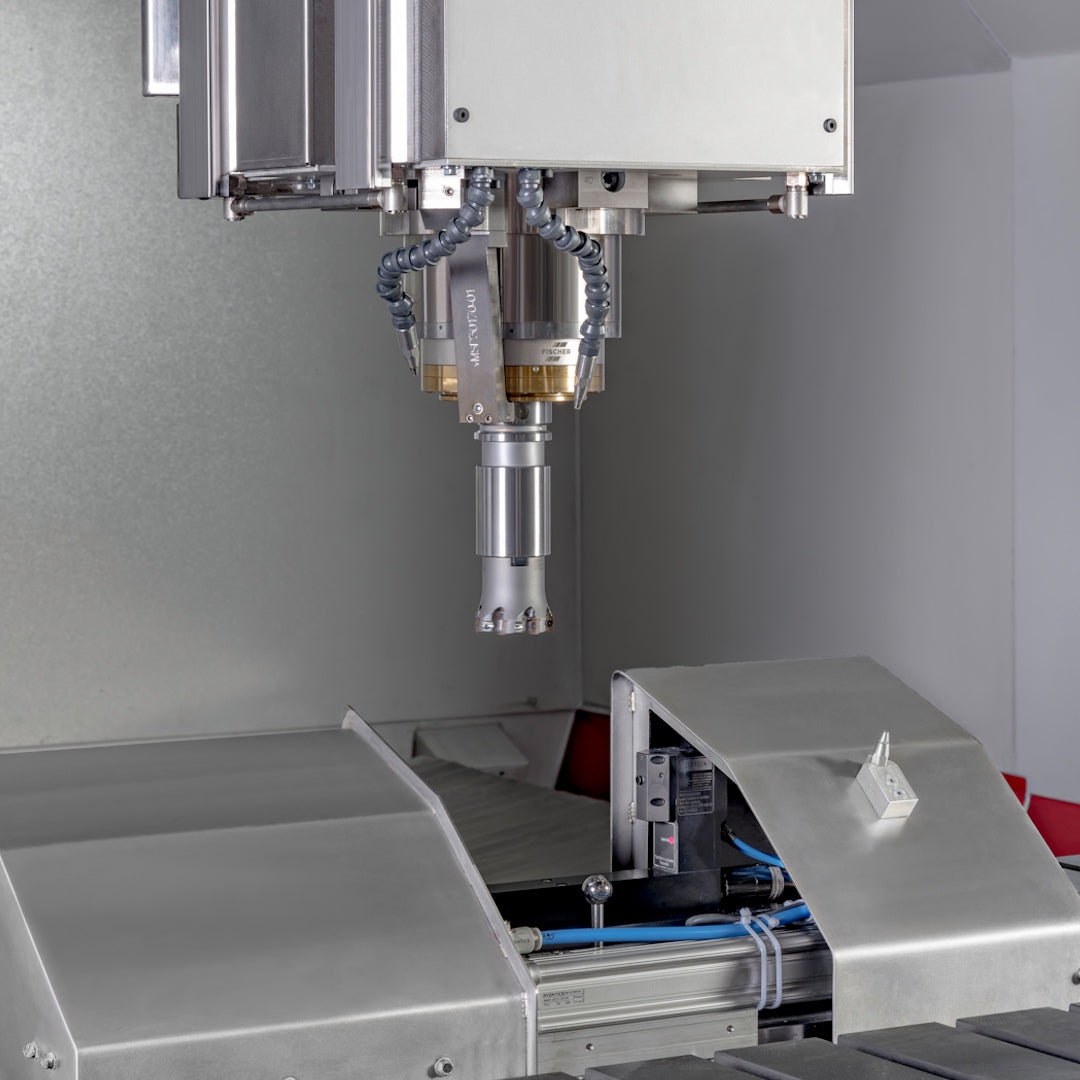

- QUADROGUIDE® portal design with four corner-mounted guide rails and 16 dampening carriages to deliver exceptional stiffness and low inertia for outstanding stability and precision.

- All-axis linear motor systems feature high-torque spindles and high-speed capabilities, ensuring long-term accuracy and performance.

- Flexible scale and capacity with models for moderate-sized workpieces to massive parts up to 6 000 kg with extensive travel dimensions up to 3000mm x 1800mm x 800mm

- Achieve up to 60m/min rapids and feeds speeds along with integrated tool measurement systems for streamlined, accurate single-setup machining

- Require no special foundations. The rigid frame provides all necessary stability, making them ideal for installation in standard factory environments.

Share

Technical Specifications

Machining Range

RXU1001: 1000mm x 810mm x 500mm (X,Y,Z)

RXU1401: 1400mm x 1050mm x 600mm (X,Y,Z)

RXU2000: 2000-2400mm x 1400-1800mm x 800mm (X,Y,Z)

RXU2600: 2600-3000mm x 1400-1800mm x 800mm (X,Y,Z)

Table Size

RXU1001: 996 mm x 798mm (X,Y)

RXU1401: 1400mm x 1070mm (X,Y), T‑slots 14mm, distance 80mm

RXU2000: 2000-2300mm x 1750 mm (X,Y) T‑slots 22mm, distance 170mm

RXU2600: 2600-2900mm x 1750mm (X,Y) T‑slots 22mm, distance 170mm

Maximum Height

RXU1001: 700mm between spindle nose and machine table, 680mm clearance between machine table and portal

RXU1401: 800mm between spindle nose and machine table

RXU2000 & RXU2600: 950-1000mm between spindle nose and machine table

Workpiece Weight

RXU1001: Maximum 2,000kg

RXU1401: Maximum 3,000kg

RXU2000: Maximum 5,000kg

RXU2600: Maximum 6,000kg

Feed

All models: 0–60,000mm/min

Milling Spindle

Spindle options available from high torque 102Nm or high speed 120,000rpm for a range of applications

Tool Changer

RXU1001: 24 (rotary – can be loaded during machining), optional 40, 75 or more places, integrated measuring laser

RXU1401: 50, optional 90 or more places (chain changer – can be loaded during machining), integrated measuring laser

RXU2000 & RXU2600: 86, optional more places (chain changer – can be loaded during machining), measuring laser placed aside the table with chip protection

Chip Disposal

All models: With 2 screws into chip box behind the machine or with additional chip conveyor

Machine Weight & Dimensions

RXU1001: ~19.5t and 3500 mm x ~4814mm x 3300mm (W,L,H)

RXU1401: ~27.0t and 3921mm x ~5439mm x H 3600 mm (W,L,H)

RXU2000: ~49.0t and 5224mm x ~6515mm x 4400mm (W,L,H)

RXU2600: ~55.0t and 5224mm x ~8015mm x 4400mm (W,L,H)

Explore Other CNC Machines

-

Röders 3-Axis RXP Series

Röders 3-Axis RXP SeriesThe Röders 3-Axis RXP Series delivers high-speed, high-precision milling with linear motor drives. The range includes compact models for micromachining and larger machines for heavy-duty, high-speed cutting such as transfer stamping dies.

-

Röders 3-Axis RPT Series

Röders 3-Axis RPT SeriesThe Röders 3-Axis RPT Series is a 3-axis milling, grinding, and measuring centre designed for maximum precision, exceptional surface quality, and shorter processing times. It is ideal for optical applications, high gloss mould tools, and ultrahigh precision milling and jig grinding.

-

Röders 5‑Axis RXU Series

Röders 5‑Axis RXU SeriesThe Röders 5‑Axis RXU Series is engineered for high roughing capacity, extreme stiffness, and exceptional precision. They cater to diverse applications, from mould and die making to aerospace and medical parts.