DATRON neo

Whether you‘re just getting started or you‘re scaling up complex production, the DATRON neo family offers the right solution for every level. With three models, DATRON neo Entry, DATRON neo, and DATRON neo Pro, high-speed milling is now more accessible, intuitive, and efficient than ever before. From an entry-level machine to a fully featured professional system, every DATRON neo model delivers precise results, simple operation, and maximum flexibility, all in a compact footprint. Thanks to the innovative DATRON next control interface, plug-and-play setup, and modern design, the DATRON neo series is built for the demands of today’s modern production environments. Start simple, scale fast, and succeed with the DATRON neo.

Highlights

- Designed for easy access to precision high-speed milling

- 500mm x 400mm working area

- Compact machine that fits through a standard door frame

- Ergonomic frontal access to the work area for quick setup

- State-of-the-art DATRON Next CNC control software with intuitive touch screen interface

Share

Technical Specifications

Machine Travels

All Models: 520mm x 420mm x 220mm (XYZ)

Working Areas

All Models: 500mm x 400mm x 175mm (XYZ)

Feeds & Rapids

DATRON neo Entry: Up to 12m/min feeds & rapids

DATRON neo and DATRON neo Pro: Up to 28m/min feeds & rapids

Spindle

DATRON neo Entry: 1.0kW 27,000rpm. Direct Shank ATC Spindle

DATRON neo and DATRON neo Pro: 2kW 40,000rpm. Direct Shank ATC Spindle

Productivity Solutions

Applicable to DATRON neo and DATRON neo Pro.

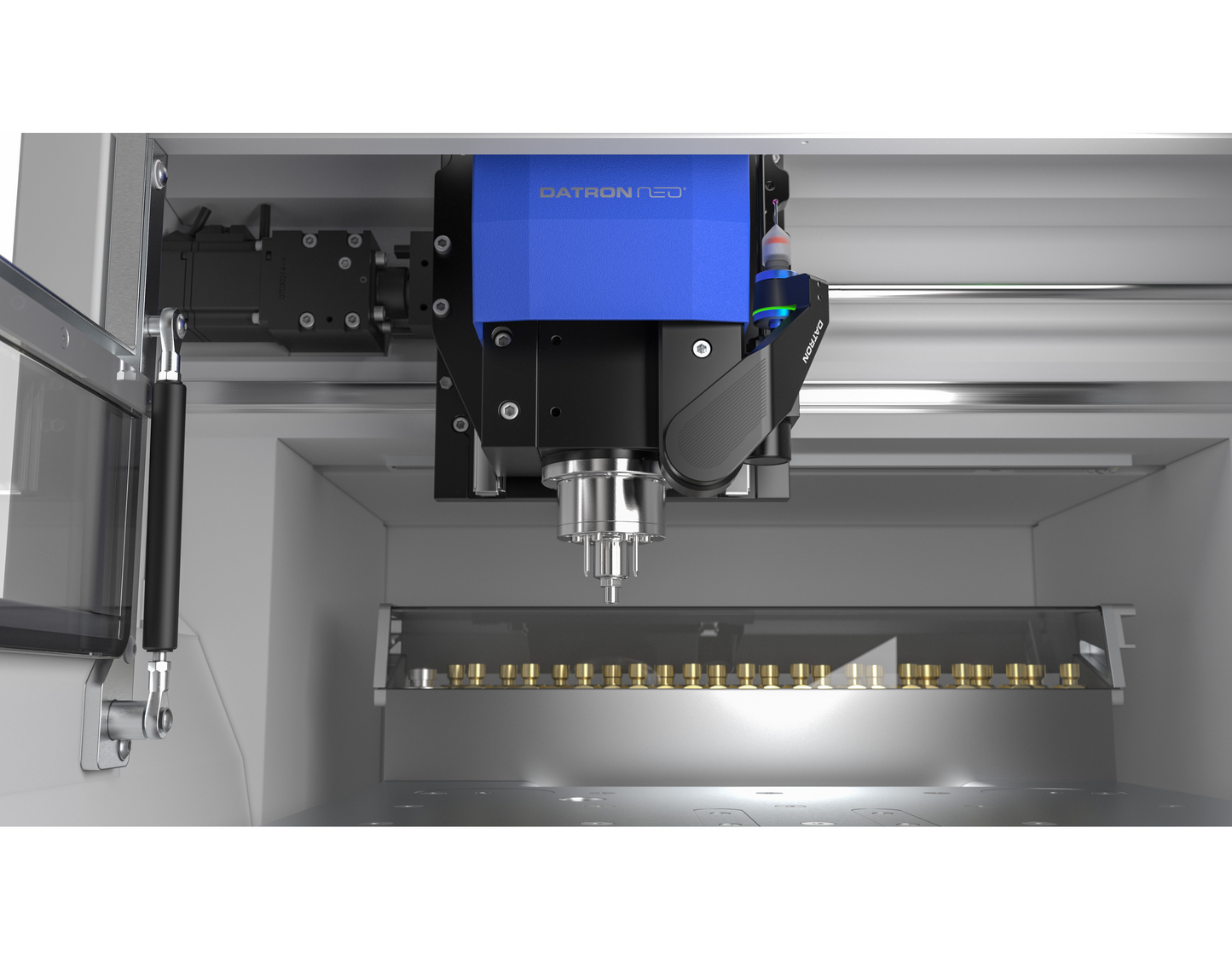

Built in Renishaw touch probe with Intuitive touchscreen based probe programming

Range of smart workholding options including Vacuum Tables, Short Stroke Pneumatic Clamping and built in Zero Point Modular Clamping plates

Optional 4th Axis processing

Automatic Tool Changer

DATRON neo Entry: 12 Station Direct Shank Automatic Tool Changer with optional integrated tool offset probing

DATRON neo and DATRON neo Pro: 24 Station Direct Shank Automatic Tool Changer with integrated tool offset probing

Control System

All Models: DATRON next control with full colour 24” touchscreen

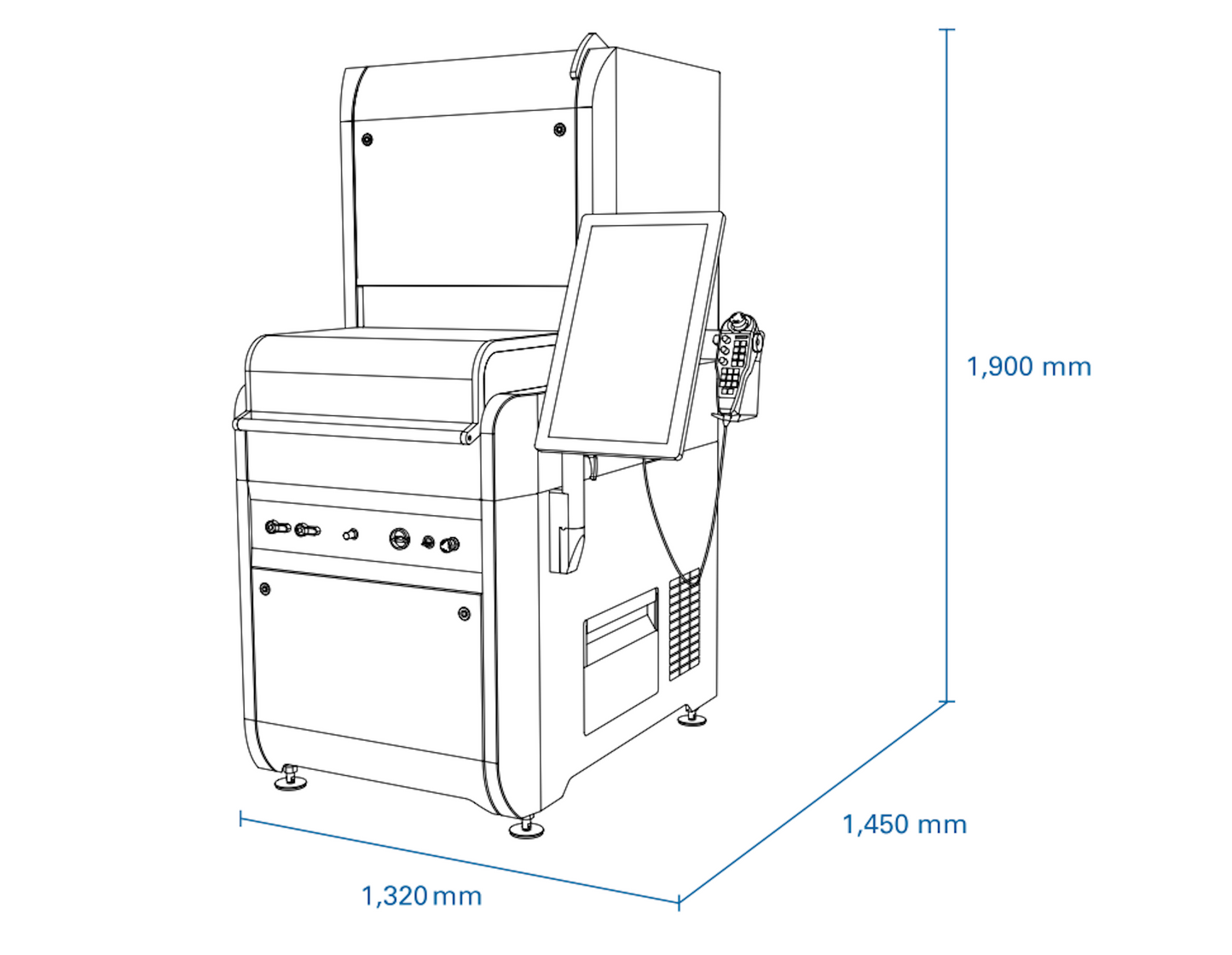

Machine Weight & Dimensions

DATRON neo Entry: ~700kg and 805mm x 1300mm x 1880mm (WxDxH)

DATRON neo and DATRON neo Plus: ~740kg and 805mm x 1450mm x 1900mm (WxDxH)

DATRON neo Highlights

-

Clear, User-Friendly Work Area

- Maximum access with minimal space. The open, ergonomic design makes loading, setup, and cleaning quick and easy.

-

Compact Design

- Every DATRON neo fits through a standard doorway and integrates seamlessly into nearly any workspace.

-

DATRON next Intuitive Touch Control

- Step-by-step touchscreen guidance makes milling easy even for beginners.

-

DATRON next Visual Set-Up

- Built-in camera and 3D probing ensure fast, accurate, and reliable workpiece alignment.

- Available on DATRON neo and DATRON neo Pro

- Built-in camera and 3D probing ensure fast, accurate, and reliable workpiece alignment.

-

Plug & Play Setup

- Unpack it. Plug it in. Start machining. No complex installation or configuration needed.

-

Outstanding Value

- Three performance levels to match your needs and budget, all with best-in-class technology and support.

DATRON neo and DATRON neo Plus Accessories

-

4-Axis Machining

- Extend the possibilities of multi-sided machining and round engraving

- Specially designed module for fast and precise positioning on the machine table

-

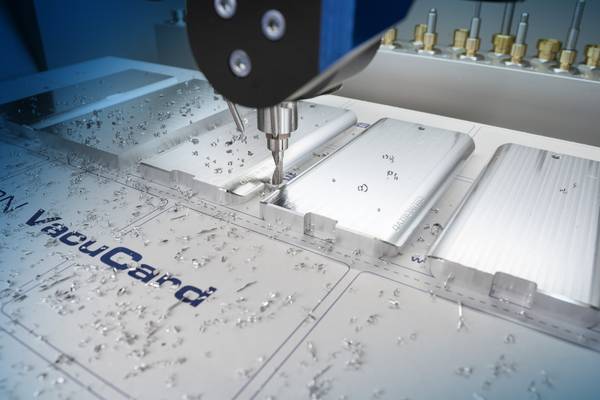

Vacuum Plates

- Vacuum module clamping plates for machining nested parts from flat thin sheet materials

- Each plate is subdivided into 10 segments that can be activated individually

-

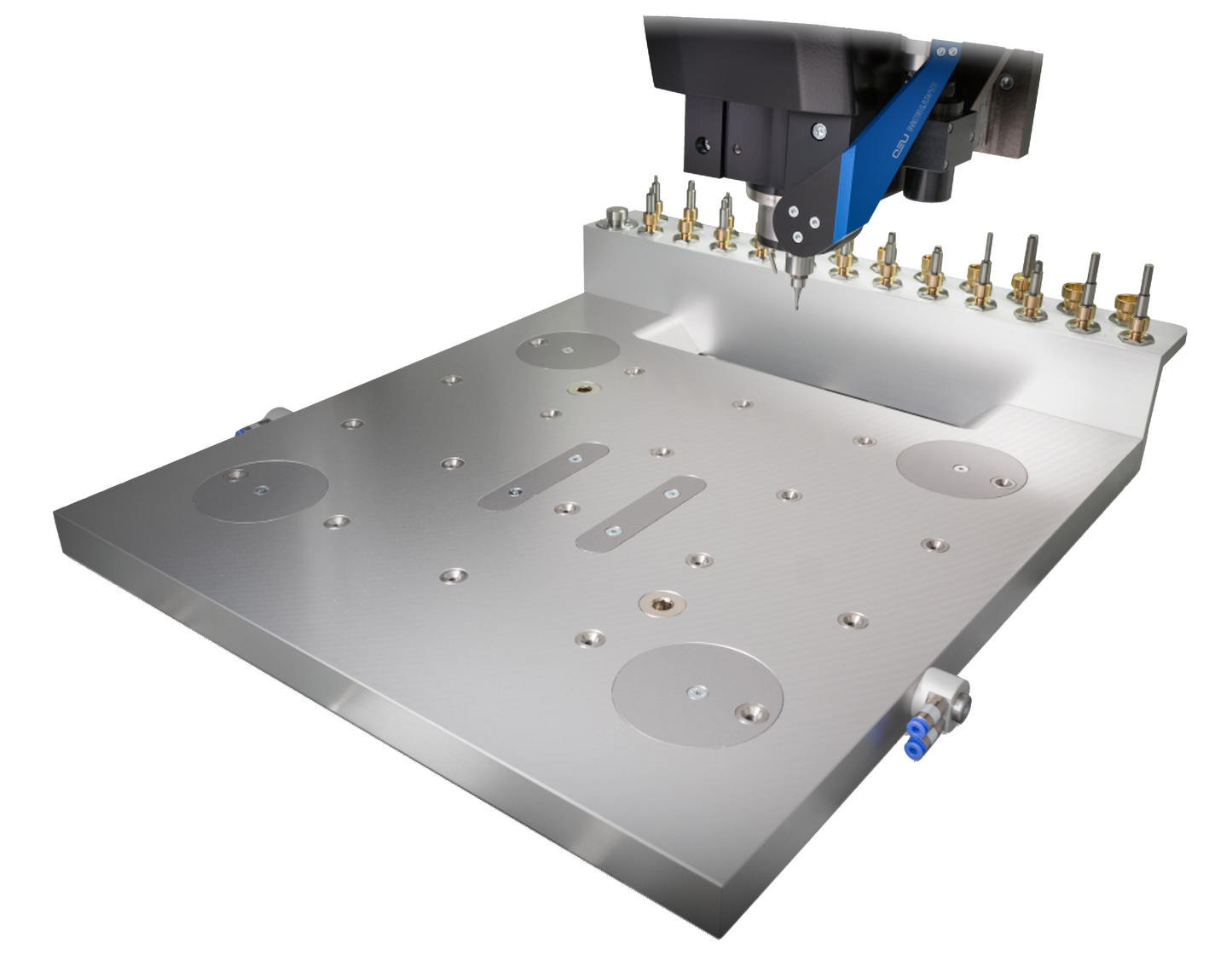

Pneumatic Clamping Set

- Short-stroke clamping element for quick and secure clamping of work pieces with one hand

- T-nut plate for flexible clamping capability

-

Dust Extraction System

- Removes dust and small chips from the cutting area while machining

- Improves visibility, cleanliness, and surface finish while protecting machine components

-

Ionizing Bar

- Facilitates chip management during plastic machining

- Reduces cleaning efforts throughout the process

-

DATRON neo Keyboard Kit

- Dust and waterproof (IP68) USB keyboard that connects to the machine’s touchscreen interface

- Ideal for reliable manual data entry and control in a workshop environment

-

DATRON neo Table

- Light‑anodised, vibration‑isolated storage surface mounted beside the machine to keep setup items conveniently organised

- Improves workflow ergonomics and setup efficiency

-

Automation Integrations

- 24 volt I/O connections for robots, cobots, or pallet systems

- Enables unattended, high-efficiency production through automated part handling, door control, and system integration

DATRON neo Areas of Application

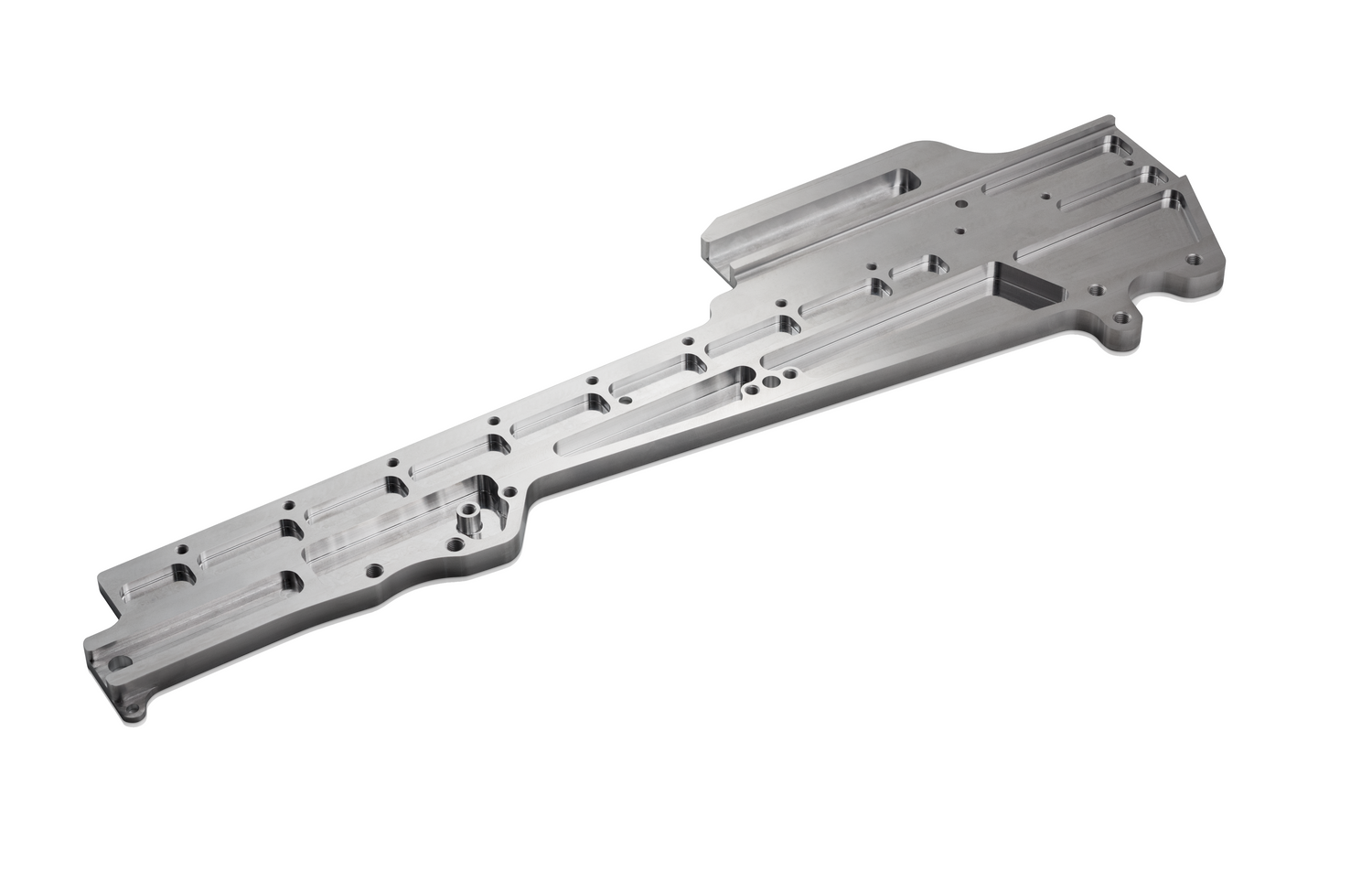

Prototyping & Mould Making

The DATRON neo is ideal for prototyping and mould making, delivering high-quality results across a wide range of materials. Its high-speed precision, intuitive setup, and versatility make it perfect for tackling the challenges of single-part and prototype production.

Aerospace

The DATRON neo can be used for the production of precision parts in airplanes, spacecraft, drones and other components. DATRON provides industrial milling solutions for the aerospace industry that set technological, qualitative, and economically sustainable standards for production.

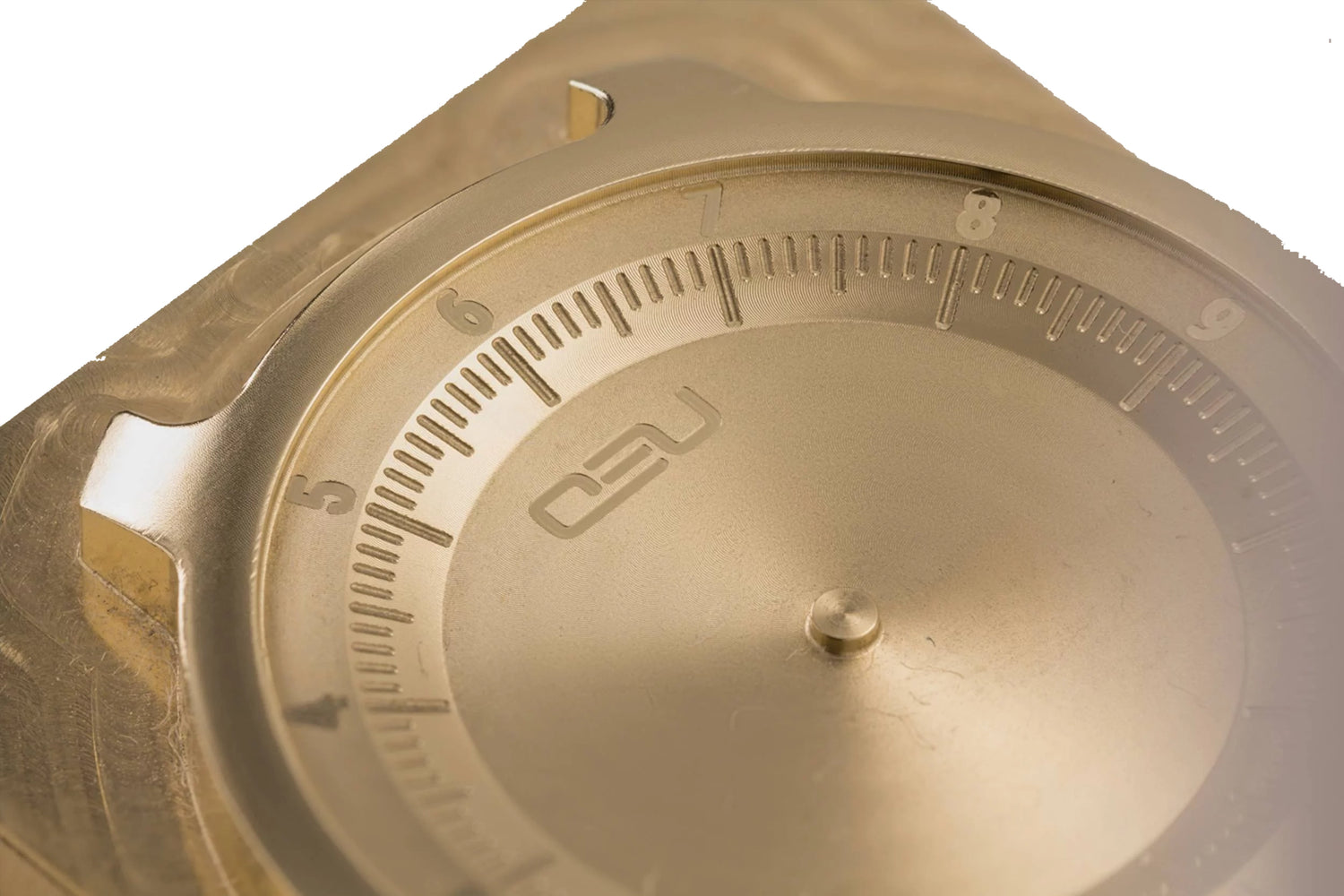

Engraving

With the DATRON neo, the specific requirements such as surface quality, accuracy, small components and individual production can be met. The DATRON neo produces mirror-like edge finishes and detailed engraving even on rounded surfaces.

Additional Sectors

- Research & Development

- Educational Institutions

- Electronics Industry

- Medical Technology

- Automotive Industry

Watch the DATRON neo in Action

Explore Other CNC Machines

-

DATRON M8Cube

DATRON M8CubeThe DATRON M8Cube is the best selection for economical machining of housings,

extrusions, and front panels of aluminium and other non-ferrous materials. -

DATRON MLCube

DATRON MLCubeThe DATRON MLCube is the ideal solution for cost-effective sheet machining and large component production, including front panels, housings, and other

aluminium workpieces milled in nested form. -

DATRON MXCube

DATRON MXCubeThe DATRON MXCube is a high-capacity, high-precision machine for high-volume

production. It's optimised for heavy material removal and delivers outstanding

stability, accuracy, and dynamic performance. -

DATRON MLCube Pro

DATRON MLCube ProThe DATRON MLCube Pro is the flagship of the MLCube series, engineered for high metal removal rates. It delivers exceptional performance and efficiency for demanding industrial production.