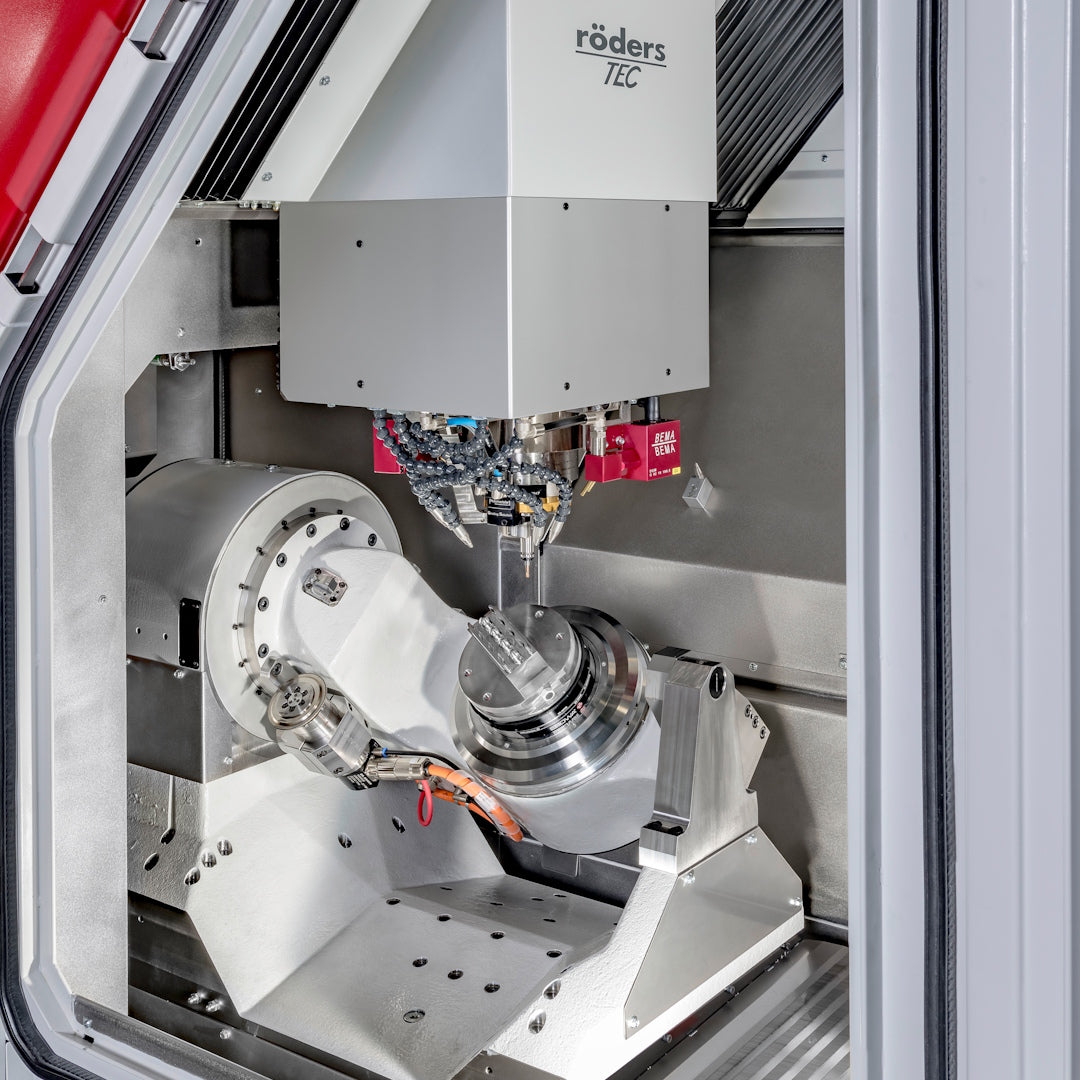

Röders 5-Axis RPT Series

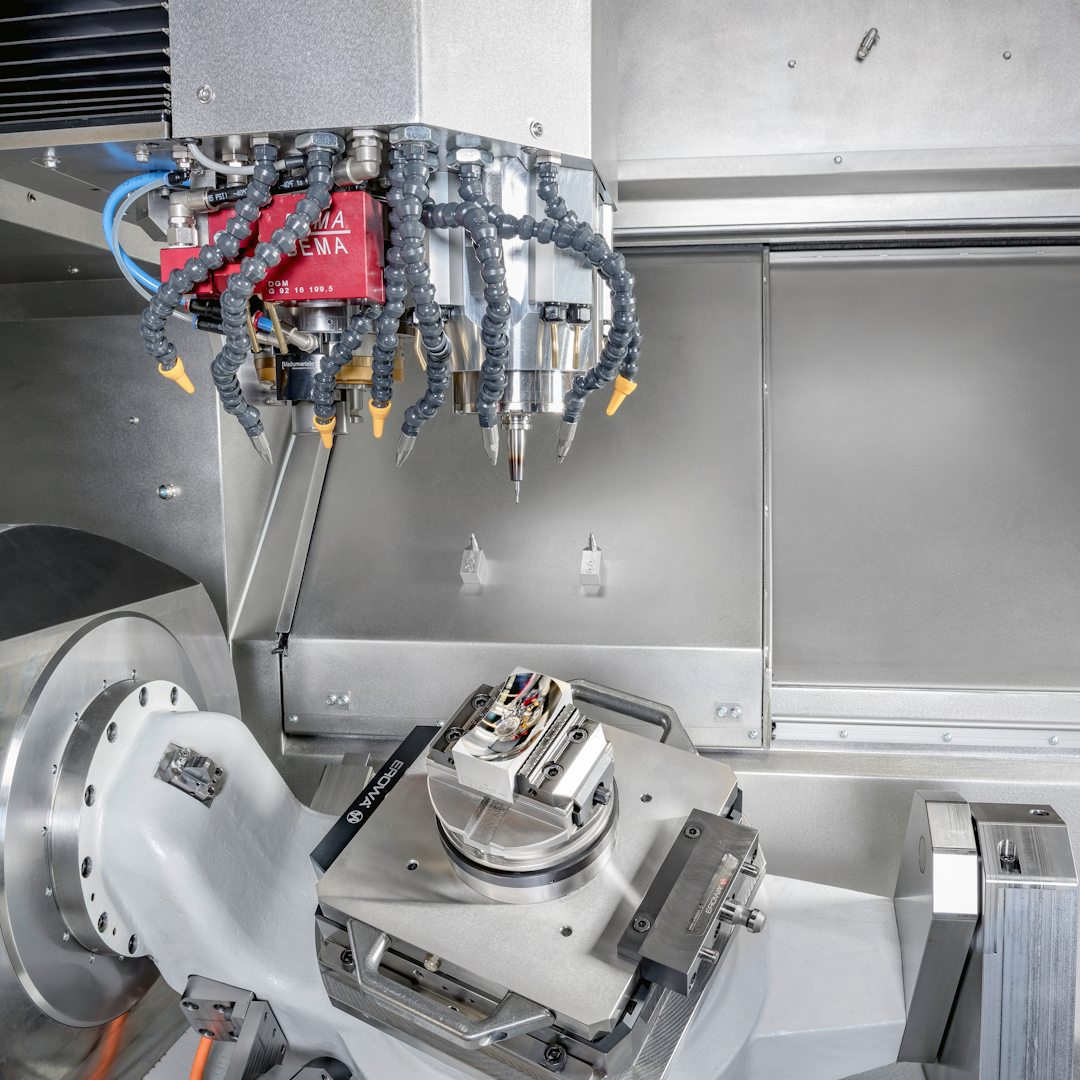

The Röders 5-Axis RPT Series is a 5-axis milling, grinding, and measuring centre engineered for maximum precision, exceptional surface quality, and shorter processing times. Featuring PRECITEMP® thermal control and the NANOTOL® guideway concept, it achieves nanometre-level running accuracy and outstanding surface finishes. Its large C-axis offset reduces compensating movements of the linear axes, improving machining speed and precision, making it ideal for mould, die, and high-value production applications.

There are two models within the Röders 5-Axis RPT Series: RPT600DSH and RPT800DSH.

Highlights

- PRECITEMP® thermal control for consistent accuracy in varying temperatures

- NANOTOL® guideways for ultra-smooth motion, rigidity, durability, and no energy consumption (unlike hydrostatics)

- Large C-axis offset for faster cycle times and higher precision

- Capable of milling, grinding, and measuring in a single setup

Share

Technical Specifications

Machining Range

RPT600DSH: 470mm x 530mm x 300mm (X,Y,Z)

RPT800DSH: 560mm x 635mm x 500mm (X,Y,Z)

Swivelling Range

All models: +/- 115 degrees

Rotation Range

All models: Almost unlimited

Table Size

RPT600DSH: 250mm round

RPT800DSH: 350mm / 400mm round or square

Clamping Unit

RPT600DSH: Erowa ITS148 PowerChuck / System 3R Magnum / Parotec Power Grip 160

RPT800DSH: Erowa UPC, Erowa ITS148 PowerChuck, Erowa ProductionChuck 210, Erowa MTS, System 3R Dynafix, Parotec Power-Grip 160

Workpiece Weight

RPT600DSH: Maximum 60kg

RPT800DSH: Maximum 200kg

Feed

All models: 0–60,000mm/min

Milling Spindle

Spindle options available from high torque 102Nm or high speed 120,000rpm for a range of applications

Tool Changer

RPT600DSH: 42 or 87 places for HSK E40, optional larger changer available, integrated measuring laser

RPT800DSH: 40 or 84 places for HSK E50, optional larger changer available, integrated measuring laser

Chip Disposal

All models: With 2 screws into chip box behind the machine or with additional chip conveyor

Machine Weight & Dimensions

RPT600DSH: ~9.3t and 2200mm x 2500mm x 2720mm (W,L,H)

RPT800DSH: ~12.5t 2400mm x 3000mm x 3450mm (W,L,H)

Explore Other CNC Machines

-

Röders 5-Axis RXP Series

Röders 5-Axis RXP SeriesThe Röders 5-Axis RXP Series are high-speed machining centres engineered for extreme precision, dynamic performance, and superior surface quality. They are ideal for aerospace, mould and die, and high- precision component manufacturing.

-

Röders 5‑Axis RXU Series

Röders 5‑Axis RXU SeriesThe Röders 5‑Axis RXU Series is engineered for high roughing capacity, extreme stiffness, and exceptional precision. They cater to diverse applications, from mould and die making to aerospace and medical parts.

-

Röders 3-Axis RXP Series

Röders 3-Axis RXP SeriesThe Röders 3-Axis RXP Series delivers high-speed, high-precision milling with linear motor drives. The range includes compact models for micromachining and larger machines for heavy-duty, high-speed cutting such as transfer stamping dies.