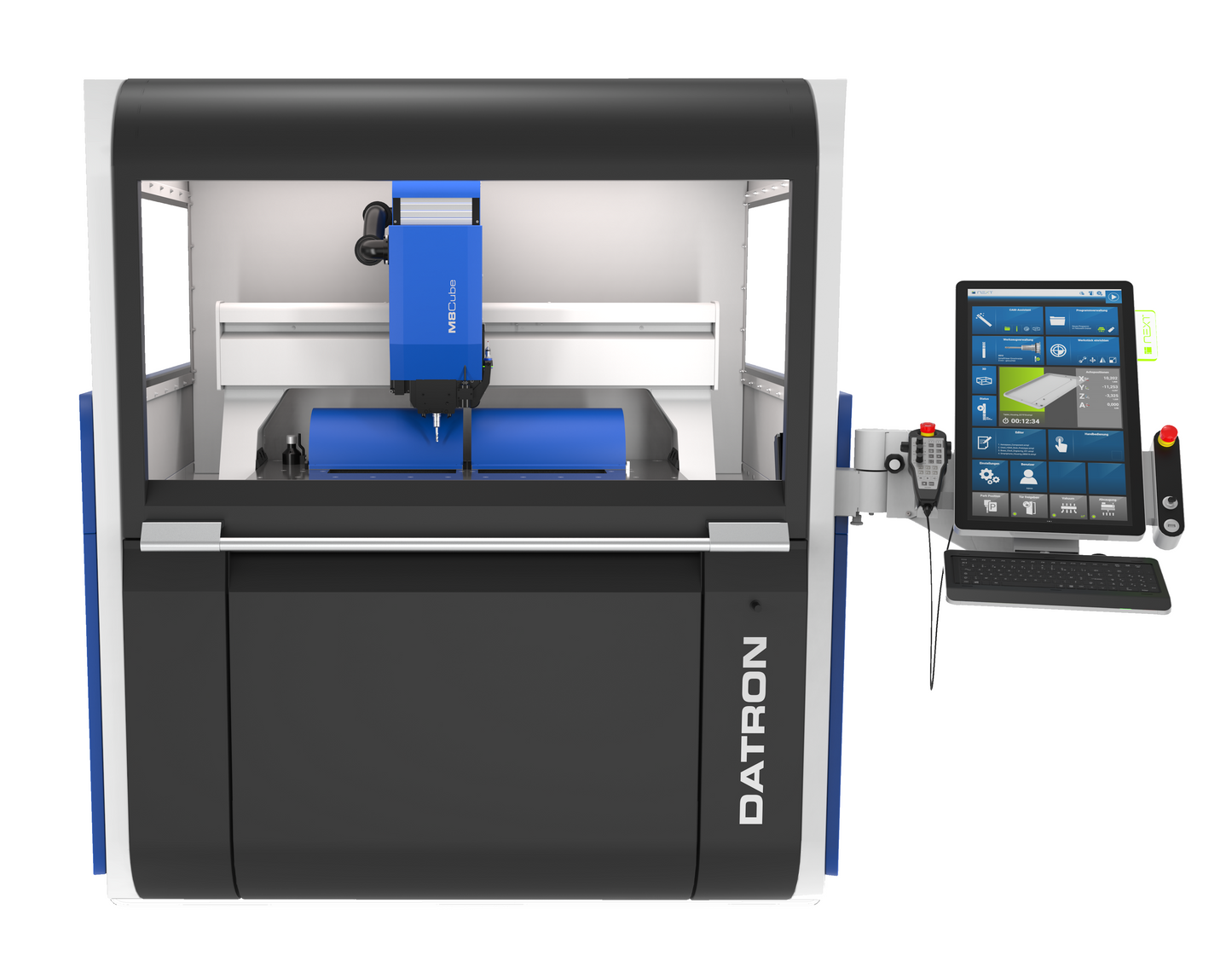

DATRON M8Cube

The DATRON M8Cube is the best selection for economical machining of housings, extrusions, and front panels of aluminium and other non-ferrous materials. Short setup times, very low energy consumption, and an outstanding price-to-performance ratio, even with small quantities, make it extremely economical to use.

Highlights

- High dynamics through optimised controls with a focus on acceleration and stiffness designed mechanical design.

- Very high tension power for small tools by using high-speed precision spindles with up to 60,000 1/min and services available from 1.8 kW to 4.0 kW.

- Rigid, low-vibration design of the machine for excellent surface quality when machining.

- High accuracy by high value linear guidance, Ball screws, HSK-E 25 tool holder (optional), and precision-crafted structure elements.

Share

Technical Specifications

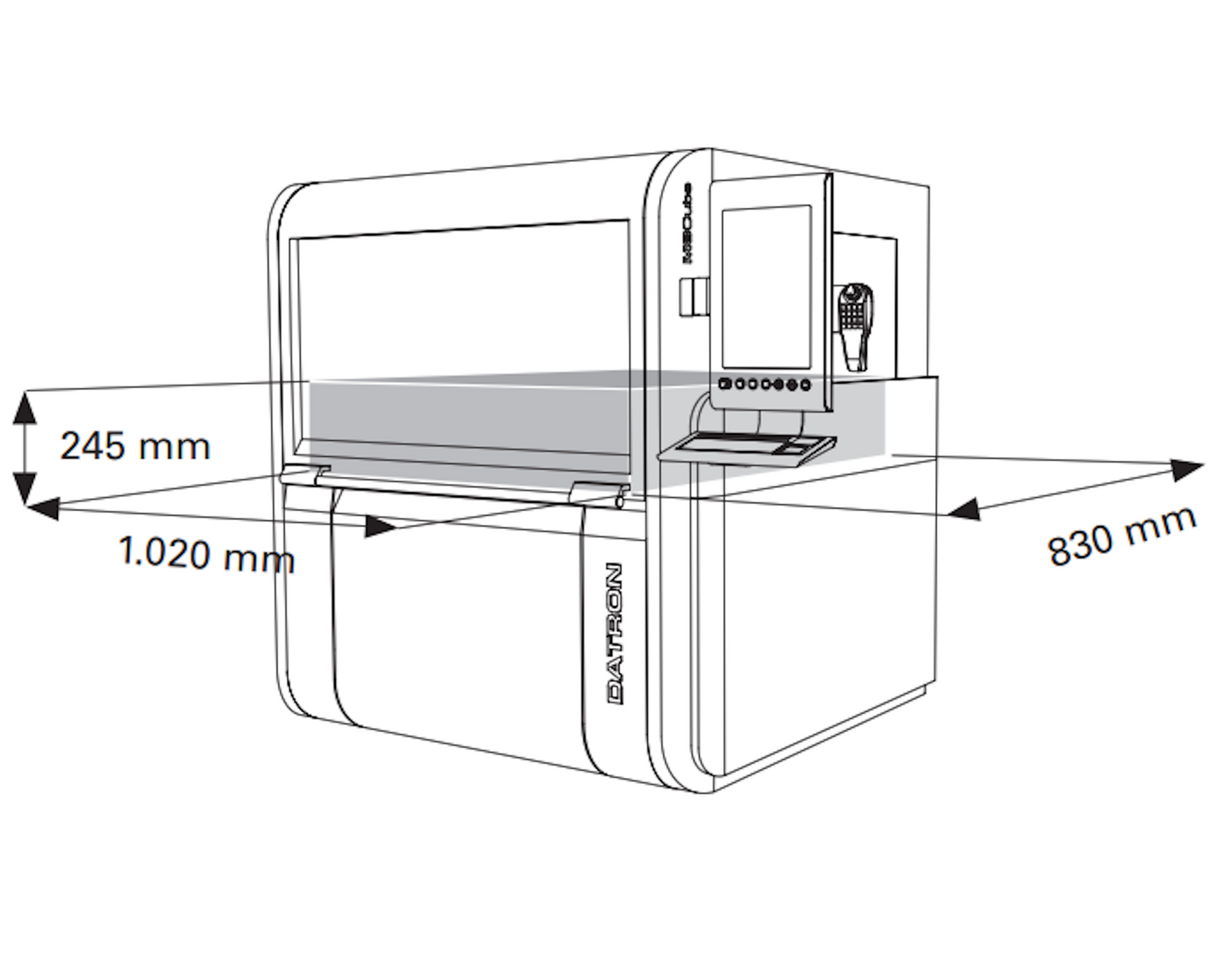

Machine Travels

1020mmx 830mm x 245mm (40" x 33" x 10") (XYZ)

Working Area

1000mm x 700mm x 200mm (39" x 27.5" x 7.5") (XYZ)

Feeds & Rapids

Up to 22m/min feeds & rapids

Spindle

0.6kW – 4kW, up to 60,000rpm ATC Spindle

Direct Shank or HSK-E25

Productivity Solutions

Built in Renishaw touch probe with intuitive touchscreen-based probe programming

Range of smart workholding options including Vacuum Tables, Short Stroke Pneumatic Clamping and built-in Zero Point Modular Clamping plates

Optional 4th and 5th Axis processing

Automatic Tool Changer

Up to 143 Station Automatic Tool Changer with DATRON ToolAssist

Integrated tool length measurement

Control System

DATRON next control with full colour 24” touchscreen

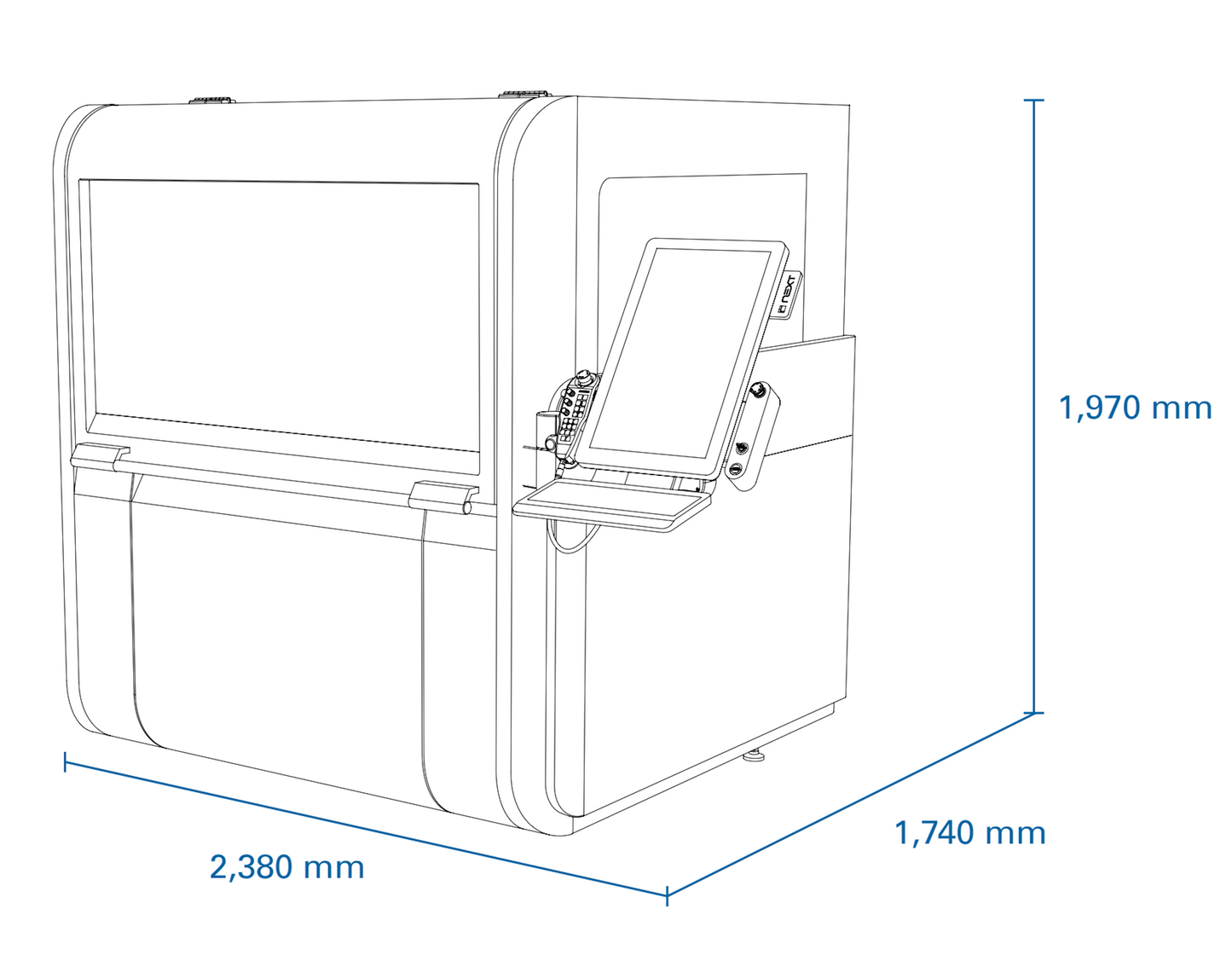

Machine Weight & Dimensions

Footprint: 1740mm x 1740mm x 1950mm (69" x 69" x 77") (W x D x H)

Weight: ~1300kg

DATRON M8Cube Highlights

-

Extreme Precision

- Extreme precision due to high-quality linear guides, ball screws, brushless direct drives and precision crafted structural elements

-

High Frequency Spindle

- With speeds up to 60,000rpm and high concentricity guarantee

- High cutting performance and perfect machining results when using small tools

-

Cooling/Lubricating System

- Economically optimised process with minimum quantity cooling lubrication

- Leads to improved cooling of the tools and workpiece which extends tool life and increases machining quality and speed

-

Measuring Probe

- The XYZ sensor guarantees short setup times, increased precision, and cost-effectiveness by automatically measuring reference edges and height profile

- Measure and compensate for height differences of the workpiece in real time

-

Multiple Configurations

- Put a vacuum chuck on one side of the bed, a pneumatic clamp on the other, and a 5-axis unit in the front

- Take on any job without changing setups

-

DATRON Next Control Software

- State-of-the-art control software designed to enable beginners and professional to operate within days, not weeks

- Remote software monitoring to check the status of your job from anywhere

-

Rigid Design

- Rigid, low vibration design for excellent surface quality when machining

- High dynamics through optimised controls with a focus on acceleration and stiffness designed mechanical design

- Highly precise milling even with dynamic temperature drifts

DATRON M8Cube Accessories

-

4 and 5-Axis Machining

- Extend the possibilities of multi-sided machining and round engraving

- Specially designed module for fast and precise positioning on the machine table

- 5-axis milling with rotary/ swivel table for precise multi-sided machining of small parts

-

Vacuum Table

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments for increased precision, efficiency, and quality

- Enables fast setup and uniform holding without damaging delicate materials

-

Dust Extraction System

- Removes dust and small chips from the cutting area while machining

- Improves visibility, cleanliness, and surface finish while protecting machine components

-

Vision System

- Captures real-time images of the workpiece for visual alignment and setup

- Speeds up positioning and reduces setup errors, even on complex parts

-

Suction CleanCut

- Combines chip extraction and air flow control to clear debris during slotting and contouring.

- Improves surface quality and cost efficiency and reduces cleaning time

-

Tool Life Management

- Automatically tracks tool wear and replaces tools when they reach their preset lifespan

- Prevents unexpected tool failure, ensuring consistent quality and uninterrupted production

-

Surface Profiling

- Measurement and mapping of 3D surfaces and compensation of variances

- Ensures consistent material thickness and superior surface finish across wide panels

-

Automation Integrations

- 24 volt I/O connections for robots, cobots, or pallet systems

- Enables unattended, high-efficiency production through automated part handling, door control, and system integration

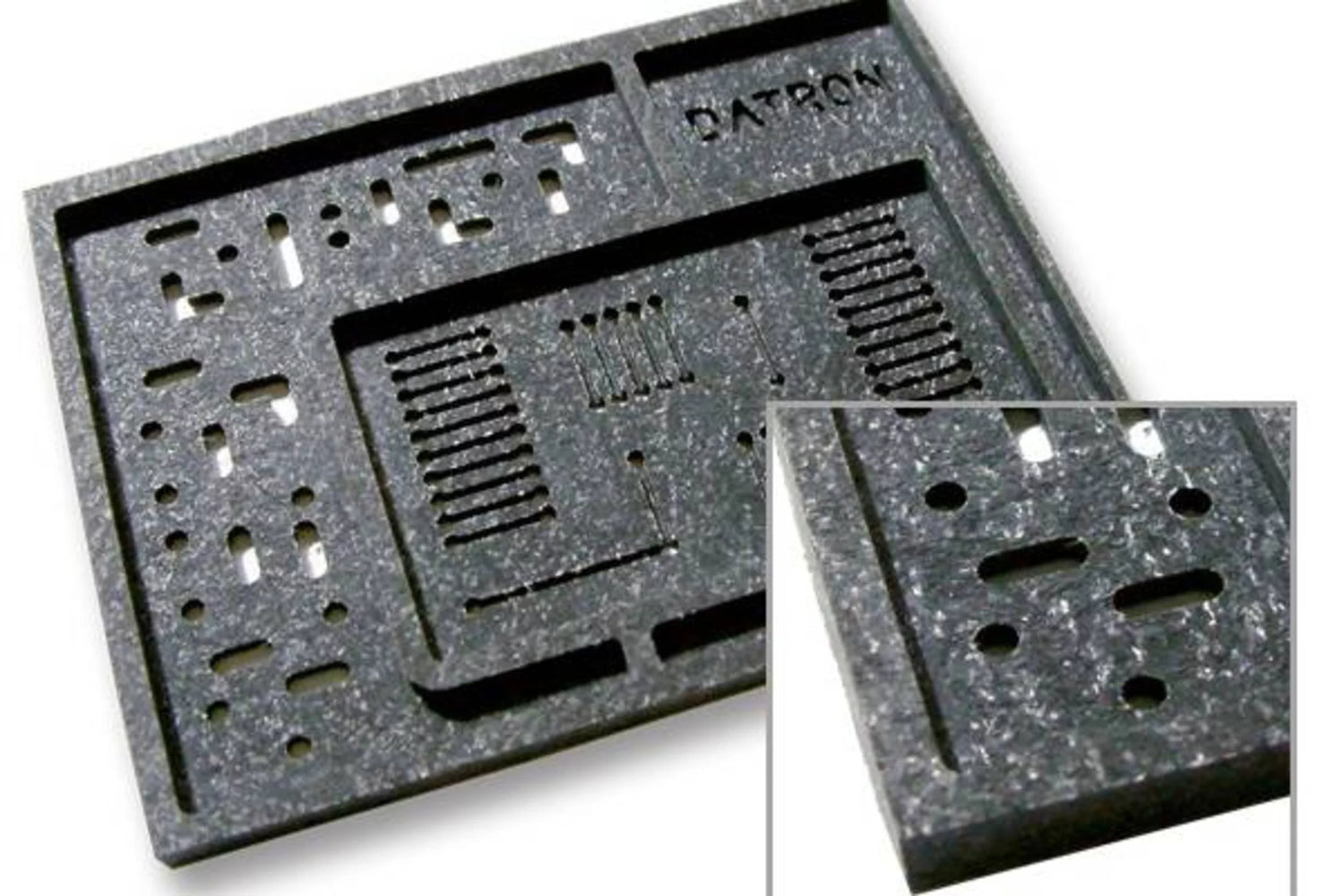

DATRON M8Cube Areas of Application

Electronics

- Front panels and housing

- Membrane keyboards

- Test adaptor drilling

- 3d rapid prototyping

- Drilling and milling of test devices

- Milling of solder frames

- PCB milling

Aerospace

- Machining of aluminium plates

- Machining of aluminium profiles

- Precision drilling

Mould & Model Construction

- 3D aluminium moulds

- 3D rapid prototyping

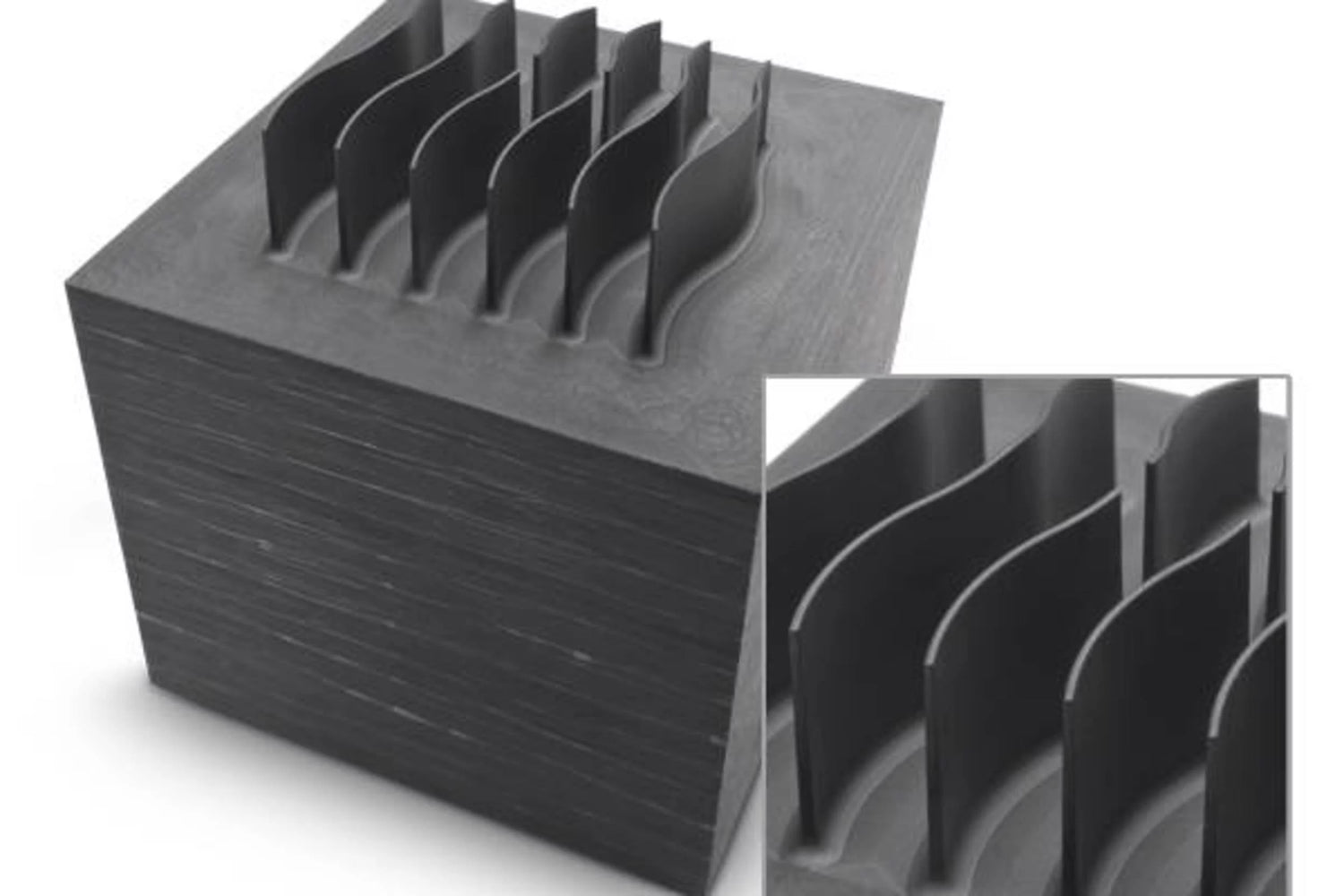

- Graphite electrodes

- Small steel moulds

Printing

- Engraving of 3D stamps

- Hot stamping dies

- Stamping tools

Automotive Supply

- Machining of aluminium profiles

- Small steel moulds

- Precision CNC machining

Watch the DATRON M8Cube in Action

Explore Other CNC Machines

-

DATRON Neo

DATRON neoThe DATRON neo is ideal for small to medium-sized parts, prototyping, low-volume production, R&D and education applications and space-constrained environments.

-

DATRON MLCube

DATRON MLCubeThe DATRON MLCube is the ideal solution for cost-effective sheet machining and large component production, including front panels, housings, and other aluminium workpieces milled in nested form.

-

DATRON MLCube Pro

DATRON MLCube ProThe DATRON MLCube Pro is the flagship of the MLCube series, engineered for high metal removal rates. It delivers exceptional performance and efficiency for demanding industrial production.

-

DATRON MXCube

DATRON MXCubeThe DATRON MXCube is a high-capacity, high-precision machine for high-volume production. It's optimised for heavy material removal and delivers outstanding stability, accuracy, and dynamic performance.