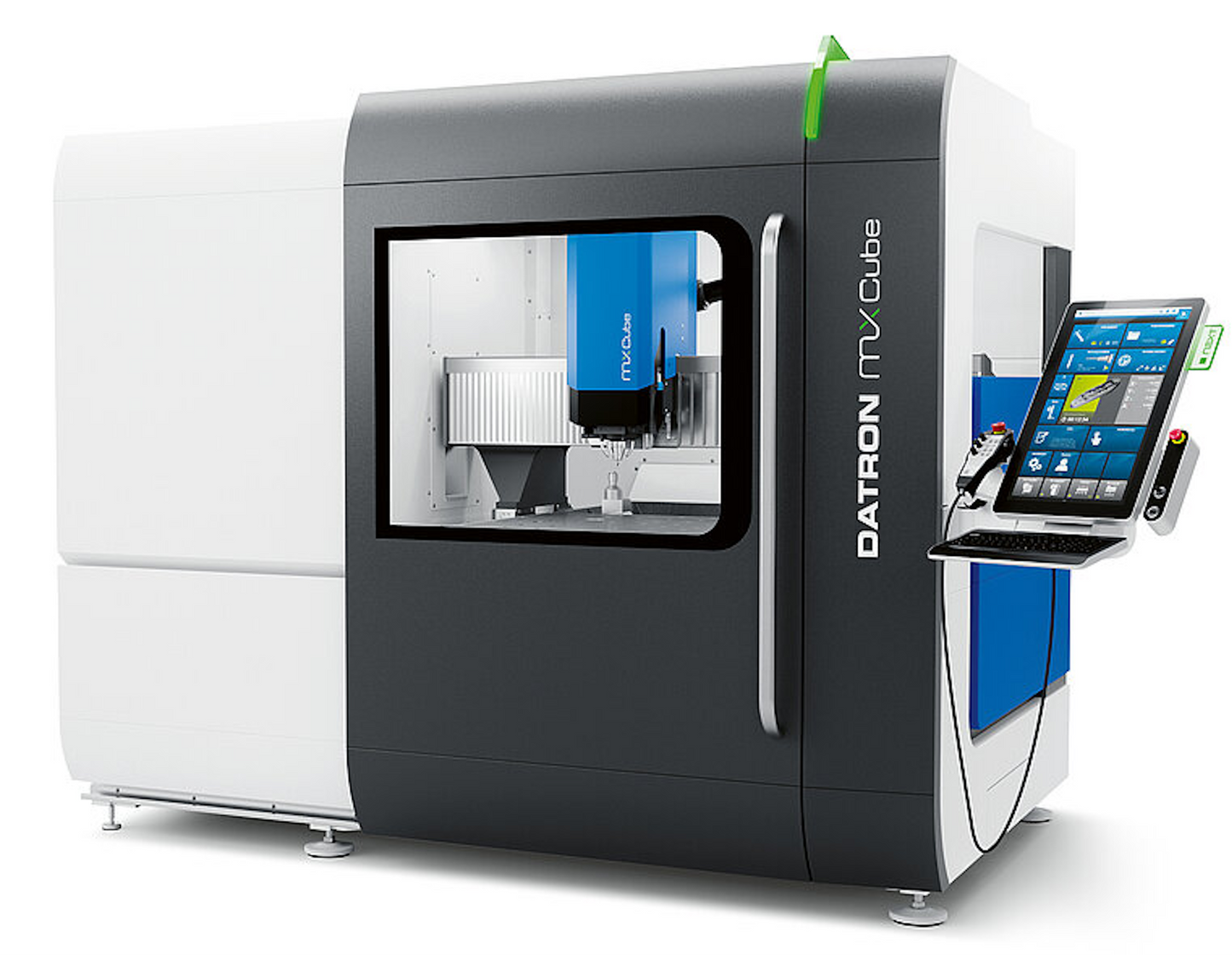

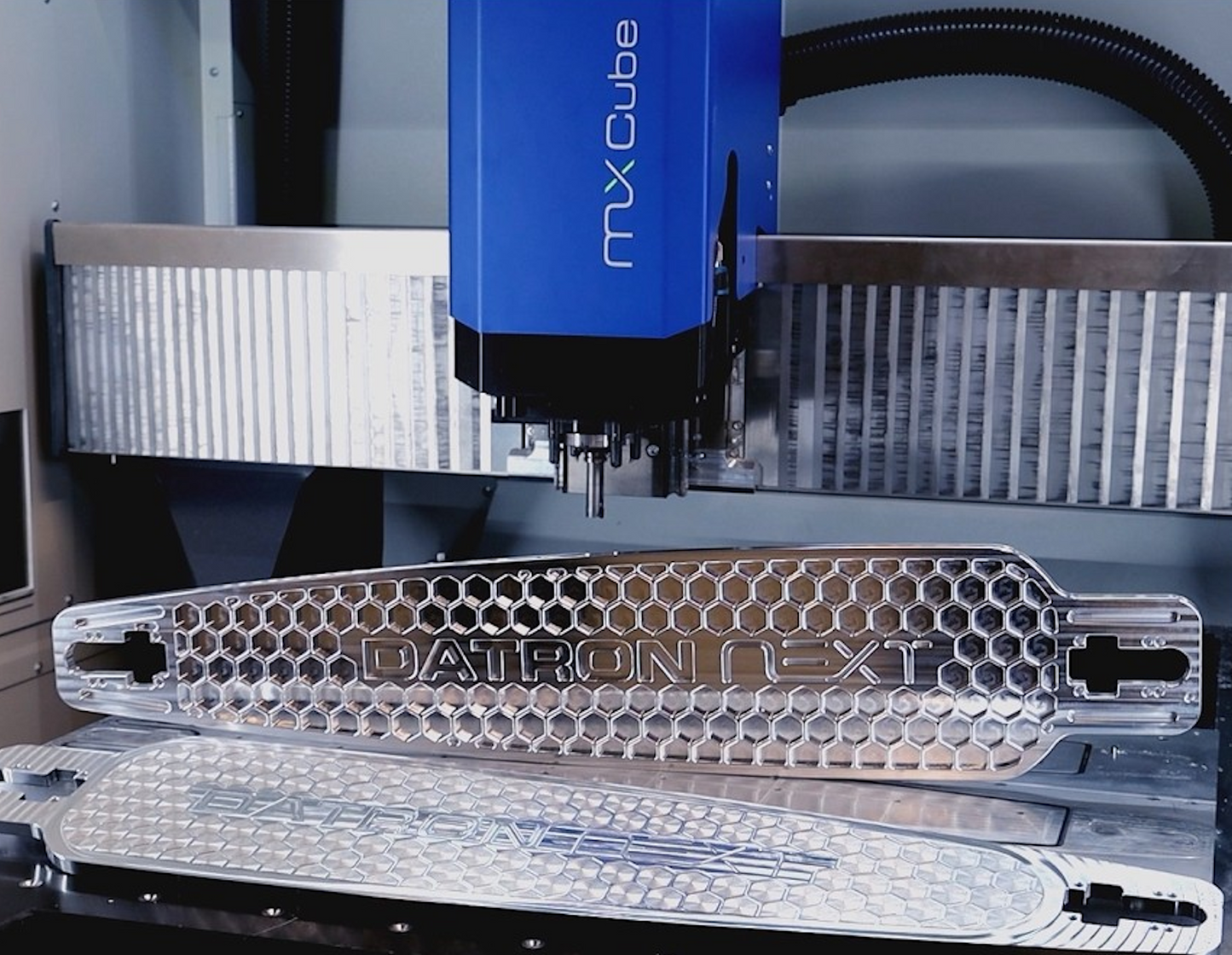

DATRON MXCube

The DATRON MXCube is a premium high-speed portal machine. Its rigid structure, maximum dynamics and a powerful high-frequency spindle are ideal for modern HSC strategies and a high machining volume with an outstanding surface finish. The completely redesigned machine with optimised chip concept offers a wide range of functionalities for operation in an industrial environment.

Highlights

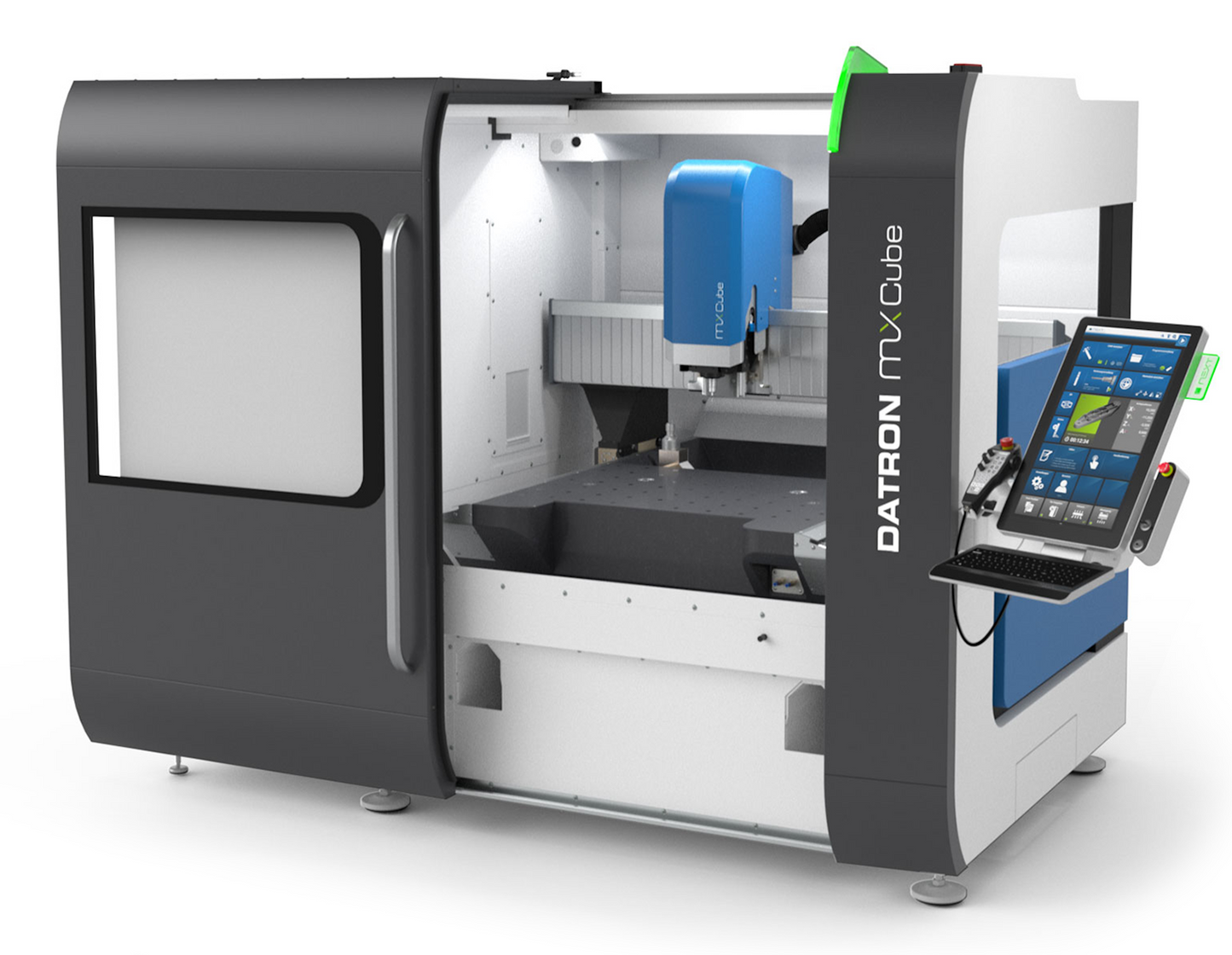

- Extremely large machining area compared to machine footprint.

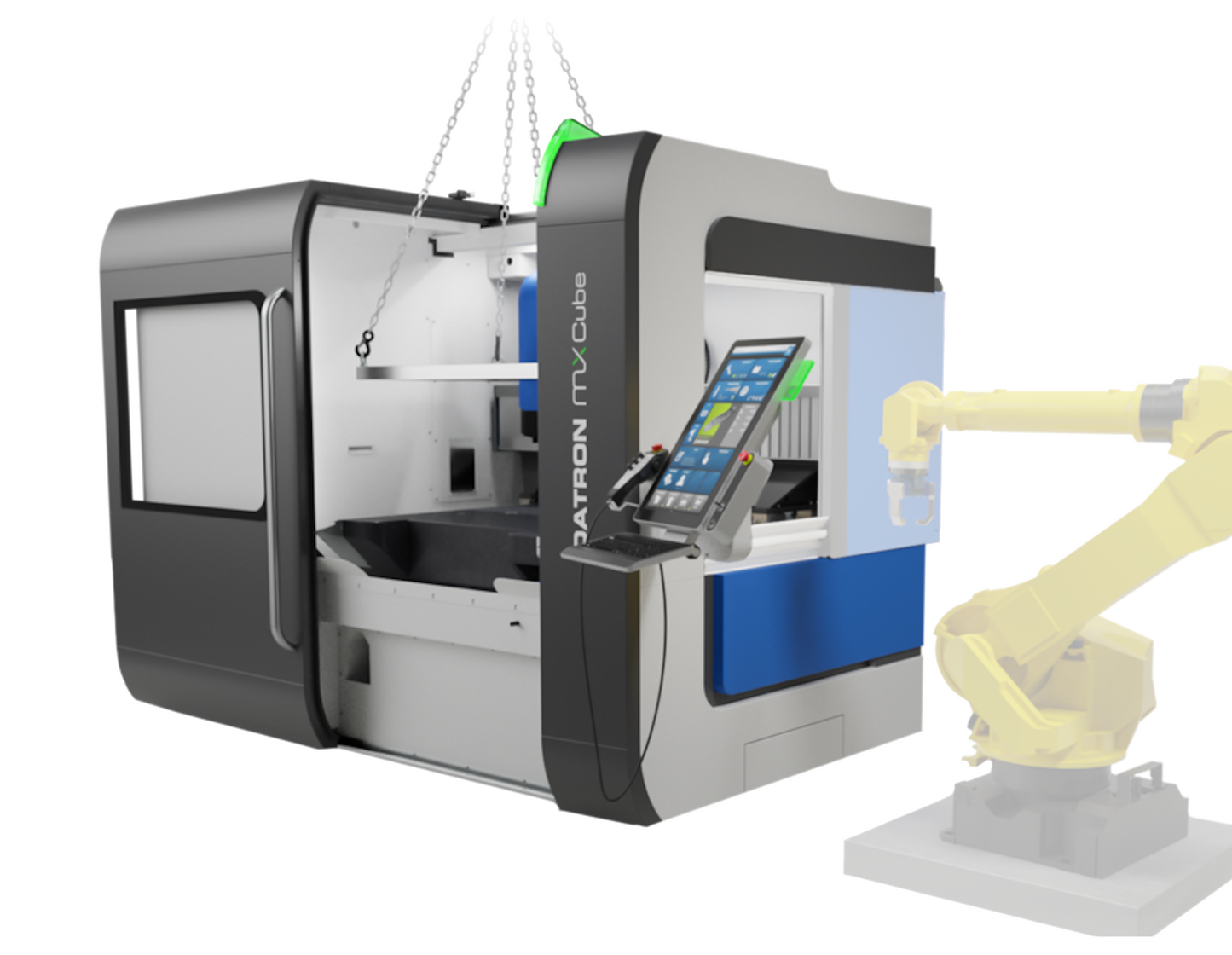

- Easily place heavy plates or clamping systems manually or with a crane, fully integrable into automation solutions.

- Functional cabin with robust steel construction with excellent access for operation and service.

- High dynamics, high speed and feed rates, rigid portal structure, and economical minimum-quantity cooling for optimal results in aluminium and non-ferrous metals.

- Chip conveyor for reliable removal of machining chips (optional).

- Intuitive, secure, and convenient DATRON next control system making HSC milling easy and efficient.

Share

Technical Specifications

Machine Travels

1040mm x 850mm x 270mm (41" x 33.5" x 11") (XYZ)

Working Area

1000mm x 700mm x 200mm (39" x 27.5" x 7.5") (XYZ)

Feeds & Rapids

Up to 40m/min feeds & rapids

Spindle

4kW HSK-E25 40,000rpm ATC Spindle

8kW HSK-E32 34,000rpm ATC Spindle

Productivity Solutions

Built in Renishaw touch probe with intuitive touchscreen-based probe programming

Range of smart workholding options including Vacuum Tables, Short Stroke Pneumatic Clamping and built-in Zero Point Modular Clamping plates

Optional 4th and 5th Axis processing

Automatic Tool Changer

Up to 143 Station Automatic Tool Changer with HSK-E25 or 110 Station Automatic Tool Changer HSK-E32 with DATRON ToolAssist

Integrated tool offset probing

Control System

DATRON next control with full colour 24” touchscreen

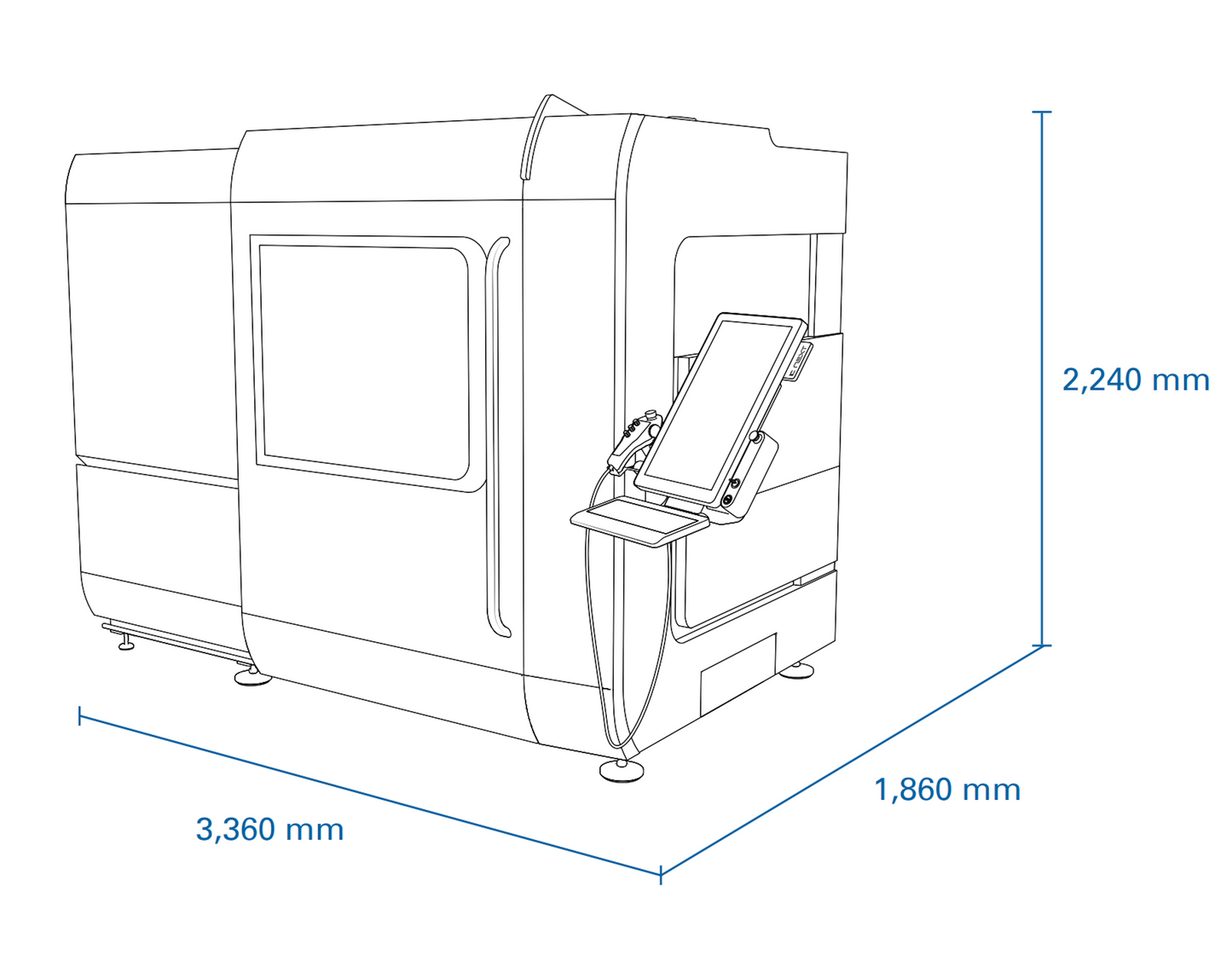

Machine Weight & Dimensions

Footprint: 3358mm x 1855mm x 2235 mm (106" x 73" x 88") (W x D x H)

Weight: ~3800kg

DATRON MXCube Highlights

-

Extreme Precision

- Extreme precision due to high-quality linear guides, ball screws, brushless direct drives and precision crafted structural elements

-

High Frequency Spindle

- With speeds up to 40,000rpm and high concentricity guarantee

- High cutting performance and perfect machining results when using small tools

-

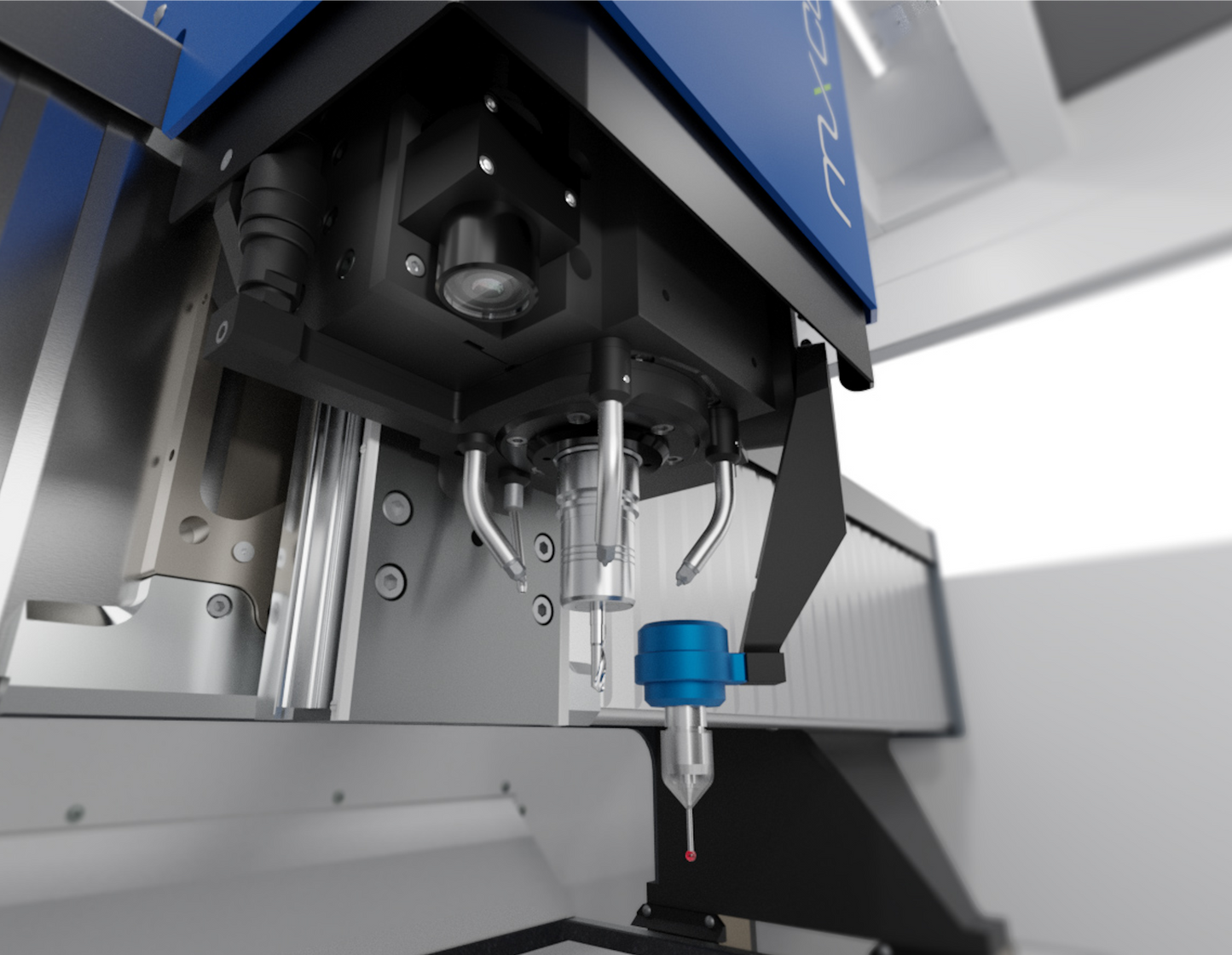

Cooling/Lubricating System

- Economically optimised process with minimum quantity cooling lubrication

- Leads to improved cooling of the tools and workpiece which extends tool life and increases machining quality and speed

-

Automatic Tool Changer with ToolAssist

- Up to 143 station automatic high-spped tool changer with integrated length sensing, and breakage control

- Enables long, automated runs (including overnight) without operator supervision

-

DATRON Next Control Software

- State-of-the-art control software designed to enable beginners and professional to operate within days, not weeks

- Remote software monitoring to check the status of your job from anywhere

-

Rigid Design

- Rigid, low vibration design for excellent surface quality when machining

- High dynamics through optimised controls with a focus on acceleration and stiffness designed mechanical design

- Highly precise milling even with dynamic temperature drifts

-

Multiple Configurations

- Put a vacuum chuck on one side of the bed, a pneumatic clamp on the other, and a 5-axis unit in the front

- Take on any job without changing setups

-

Optimal Handling

- Load from above, directly from the front using a crane, or an optional powered side door with the help of external automation

- Flexible loading options are compatible with cranes, robots, or cobots

DATRON MXCube Accessories

-

4 and 5-Axis Machining

- Expands the machine’s capabilities with optional 4-axis (rotary) and 5-axis (simultaneous) extensions for complex, multi-sided, and freeform part machining

- Enables high-precision production of intricate components in fewer setups, increasing flexibility, accuracy, and overall machining efficiency

-

Vacuum Table

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments for increased precision, efficiency, and quality

- Enables fast setup and uniform holding without damaging delicate materials

-

Dust Extraction System

- Removes dust and small chips from the cutting area while machining

- Improves visibility, cleanliness, and surface finish while protecting machine components

-

Vision System

- Captures real-time images of the workpiece for visual alignment and setup

- Speeds up positioning and reduces setup errors, even on complex parts

-

Tool Life Management

- Automatically tracks tool wear and replaces tools when they reach their preset lifespan

- Prevents unexpected tool failure, ensuring consistent quality and uninterrupted production

-

Surface Profiling

- Measurement and mapping of 3D surfaces and compensation of variances

- Ensures consistent material thickness and superior surface finish across wide panels

-

Automation Integrations

- Supports automated loading of heavy plates, workpieces, or fixtures via crane or robot through optional front, top, or side access points with powered doors

- Enables seamless integration into automated production lines, reducing manual handling and increasing efficiency in high-volume manufacturing

-

3D Probe

- Automatically measures and aligns workpieces and tools with high precision using a retractable 3D probe and linear-guided sensor system

- Ensures fast, accurate setups and protects sensitive tools and probes from damage, improving overall process reliability and machining quality

-

Chip Conveyor

- Actively extracts chips and fine dust directly from the machining area using an integrated, powerful vacuum system

- Maintains a clean workspace, improves visibility, protects components, and supports consistent machining quality, especially when working with plastics, composites, or aluminium

-

4-Nozzle Cooling/Lubrication System

- Delivers precise, minimal-quantity cooling lubrication using specialised nozzles and compatible directly at the tool edge

- Increases tool life, improves machining quality, reduces cleaning requirements, and boosts overall productivity, especially in high-speed or fine-detail milling

-

T-Slot Clamping Plate

- Offers a modular, flexible clamping system, including vacuum tables, pneumatic clamping, and quick-change fixtures, for secure and fast workpiece holding

- Reduces setup times, increases part stability, and supports a wide variety of materials and geometries for efficient, precise machining

-

Compact Bench Vice

- A low-profile, high-precision clamping device designed for secure, space-efficient workholding on the DATRON MXCube

- Maximises machining access and Z-axis clearance while enabling fast, repeatable part changes for increased productivity

Watch the DATRON MXCube in Action

Explore Other CNC Machines

-

DATRON MLCube

DATRON MLCubeThe DATRON MLCube is the ideal solution for cost-effective sheet machining and large component production, including front panels, housings, and other aluminium workpieces milled in nested form.

-

DATRON Neo

DATRON neoThe DATRON neo is ideal for small to medium-sized parts, prototyping, low-volume production, R&D and education applications and space-constrained environments.

-

DATRON M8Cube

DATRON M8CubeThe DATRON M8Cube is the best selection for economical machining of housings, extrusions, and front panels of aluminium and other non-ferrous materials.

-

DATRON MLCube Pro

DATRON MLCube ProThe DATRON MLCube Pro is the flagship of the MLCube series, engineered for high metal removal rates. It delivers exceptional performance and efficiency for demanding industrial production.