DATRON evo600

Experience a dispensing system that revolutionizes your production processes with the DATRON evo 600. Thanks to the innovative DATRON next control system and precise dispensing technology, you can achieve outstanding dispensing results. The open cabin not only offers easy access for loading and unloading, but also guarantees maximum safety thanks to integrated light curtains. The user-friendly operator interface of the pioneering DATRON next control enables intuitive handling, while the modular design offers flexibility for configuration. Maximize your efficiency and competitiveness with the DATRON evo 600.

Highlights

- Precision dispensing driven by the DATRON next control for consistently high-quality results.

- Open cabin for fast, easy loading/unloading with integrated light curtains for maximum operator safety.

- Intuitive interface that simplifies operation and shortens training time.

- Modular, configurable platform to fit your process today and scale with production, maximizing efficiency and competitiveness.

Share

Technical Specifications

Machine Design

CNC axis system with table and cabin

Maximum Component Height

Up to 450mm

Transversing Speed

Up to 50m/min (X,Y) and up to 23m/min (Z)

Travel Range

620mm x 515mm x 240mm (X,Y,Z)

Machine Table

Aluminium table with M6 tapered thread grid (100mm x 100m)

Control System

DATRON next control with full colour 24” touchscreen

Safety Concept

Safety light curtain type 4

Drive System

Digital servo drives

Compressed Air Connection

6.5 bar, purity class ISO8573-1:2010 [3 : 4 : 3]

Electrical Connection

400V, CEE 16 A, 4.5kVA

Machine Dimensions & Weight

Footprint: 1890mm x 2500mm 2150mm (W x D x H)

Weight: ~1900kg

DATRON evo600 Highlights

-

Highest Dispensing Quality

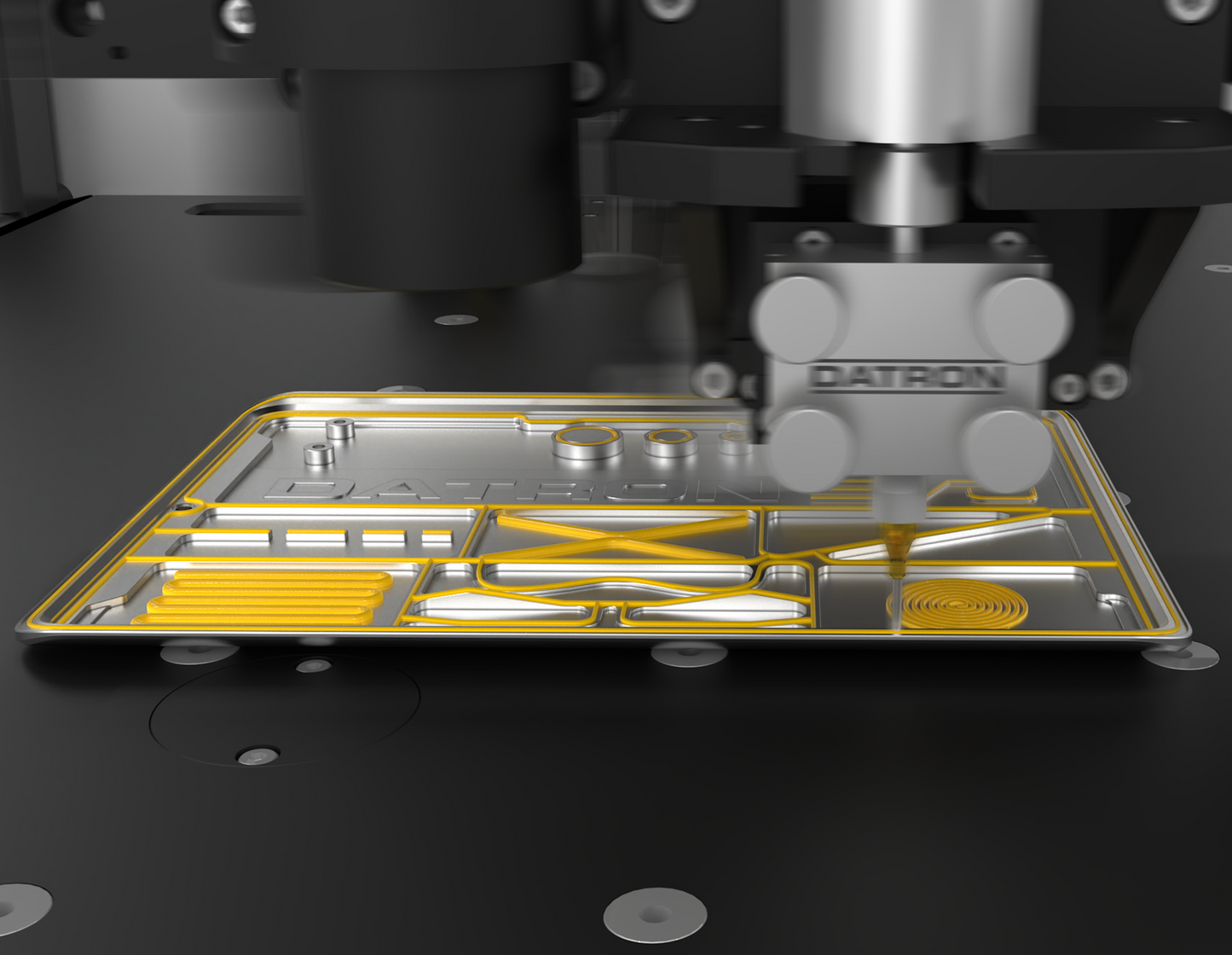

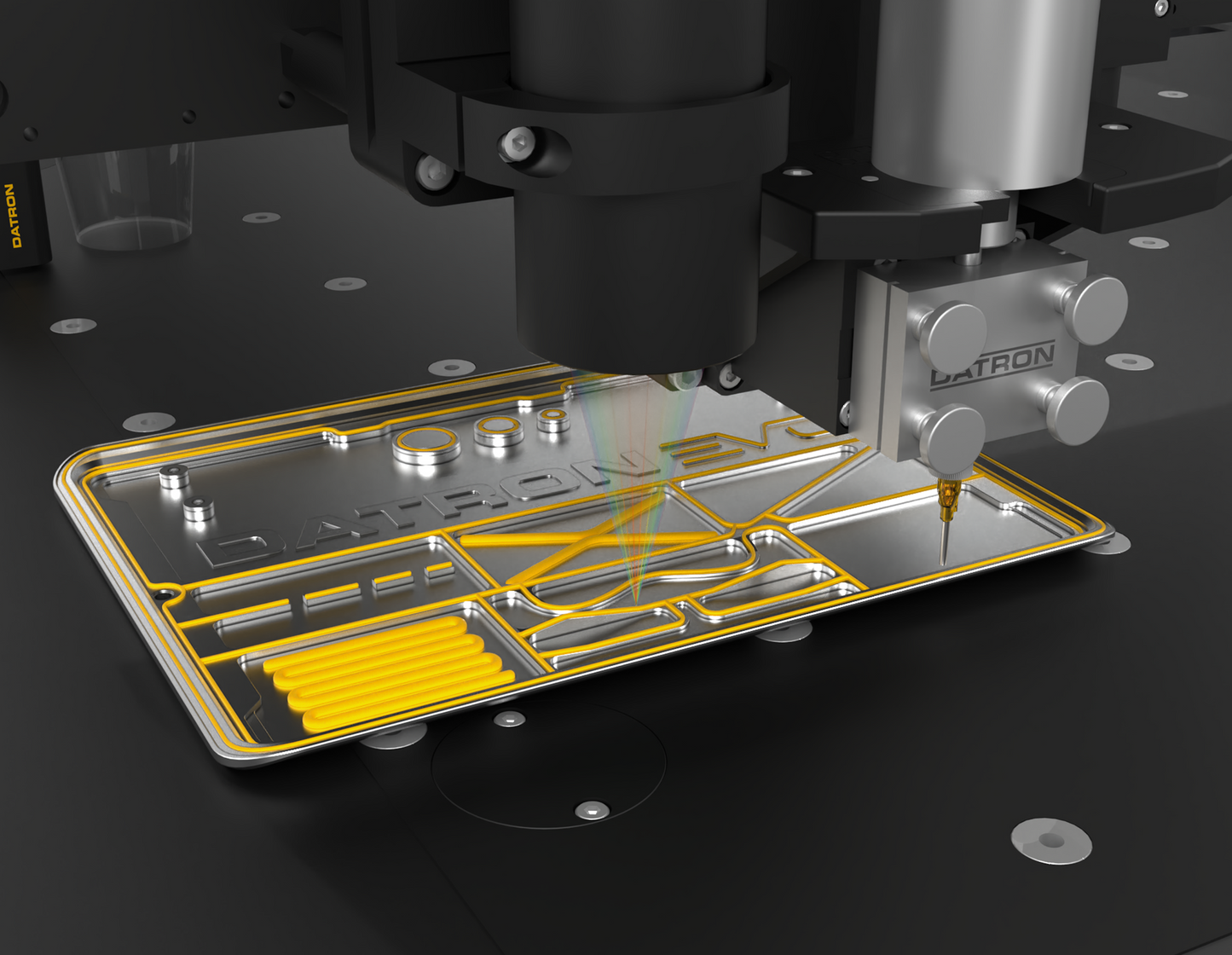

- Axis movement is intelligently synchronised with dispensing volume for optimal cycle times and precision

- Automatically adapts to different fluid properties and component geometries ensuring maximum dispensing accuracy with full control over process parameters

-

Technological Expertise

- Combines a high-precision axis system with advanced sensor technology for repeatable, reliable dispensing results

- Delivers uniform bead cross-sections with precise volume control and ramp strategies, even at start/stop and transition points

- Combines a high-precision axis system with advanced sensor technology for repeatable, reliable dispensing results

-

User-Friendly Interface & Software

- Intuitive DATRON next control system with easy setup, tool referencing, and excellent machine accessibility

- Automatic cartridge pre-pressure control eliminates manual adjustments for consistent and efficient dispensing

-

Productivity Redefined

- High productivity and intelligent pump control reduce cycle times and cost per part while maintaining consistent dispensing quality

- Designed for industrial series production, the evo600 supports faster workflows and minimises downtime to maximise output and competitiveness

-

Human Centric

- Ergonomic, user-friendly design with an open cabin and wide entry ensures easy loading, quick changeovers, and full process visibility

- The intuitive DATRON next control system simplifies operation, putting the user at the centre of an efficient and accessible dispensing workflow

-

Automatic Tool Changer with ToolAssist

- Offers maximum flexibility with configurable options for manual or fully automated loading, easily adapting to changing production needs

- Reduces investment risk and integration costs by providing a scalable, plug & play solution tailored to individual applications

DATRON evo600 Accessories

-

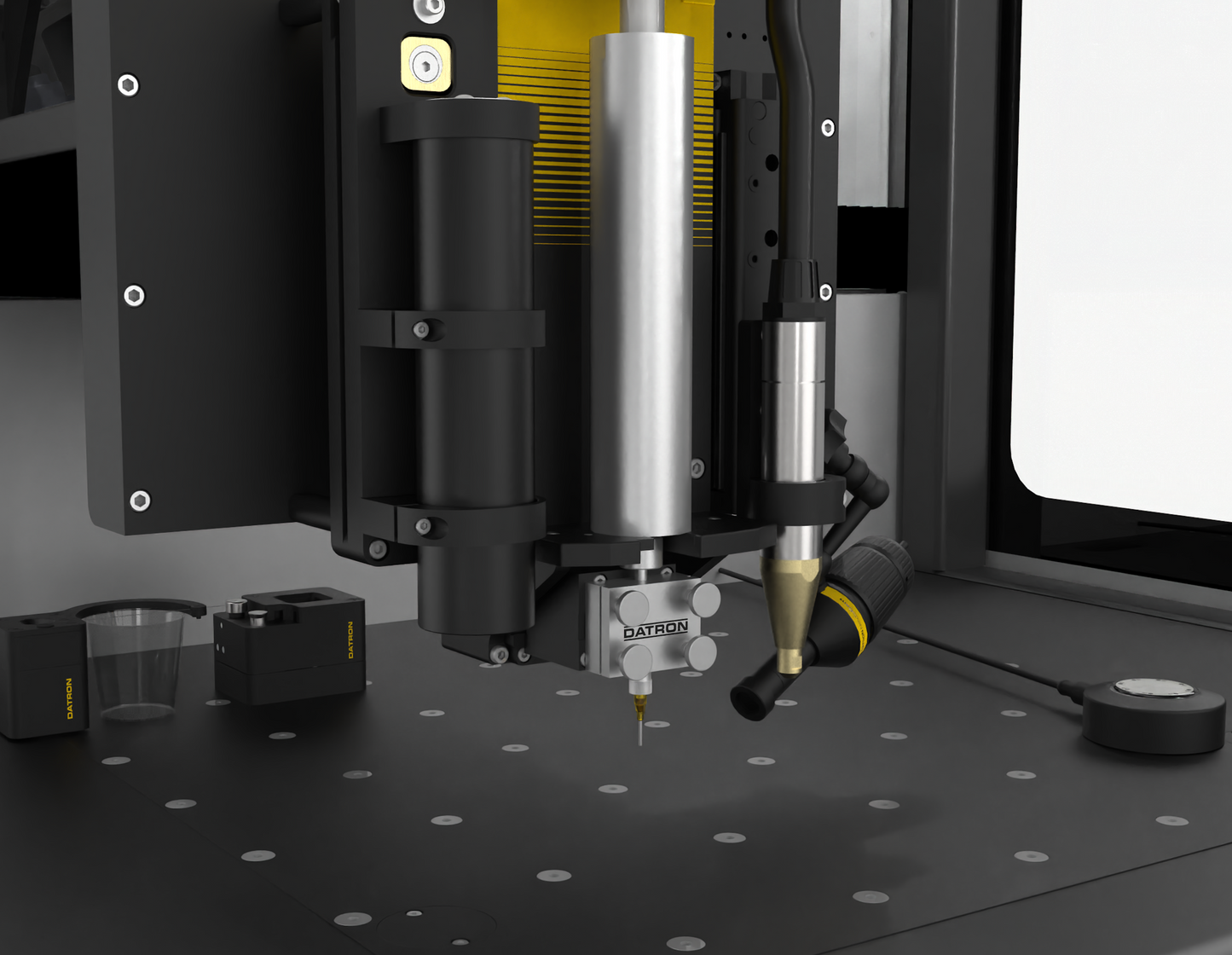

Dispensing Heads & Pumps

- Modular dispensing head with gear pumps enables dynamic, high-precision fluid application, with optional software-controlled pressure regulation for consistent quality

- Versatile dispensing pumps support a wide range of materials, including 2-component and temperature-sensitive media, with scalable supply options like drum feed systems for efficient, customised dispensing

-

Needle Measurement

- Intelligent needle measurement automatically detects and compensates for deviations after needle changes, ensuring precise alignment of the dispensing tip

- Consistent dispensing quality is maintained by accurately referencing all relevant tool positions, eliminating manual adjustments and setup errors

-

Needle Cleaning

- Reliable needle cleaning system removes material residues using mechanical and air-assisted methods to maintain optimal dispensing performance

- Consistent quality is ensured by keeping needles residue-free and ready for use, even after long idle periods

-

Workpiece Measurement

- 3D confocal sensor provides high-precision, optical height and position measurement, even on transparent or reflective surfaces, with automatic dispensing height adjustment for consistent results

- DATRON 3D probe offers reliable, contact-based workpiece measurement with automatic deployment and magnetic protection for long-term accuracy and durability

-

Camera System

- DATRON Needle Cam provides high-resolution, real-time monitoring of the dispensing needle for greater control and process reliability

- Camera-assisted setup allows for fast, intuitive workpiece positioning, increasing efficiency and reducing setup time

-

Plasma Pre-Treatment

- Plasma pre-treatment system cleans and activates workpiece surfaces to enhance adhesion before dispensing

- Integrated pneumatic slide enables precise, repeatable application for consistent and process-reliable bonding quality

-

Control Elements

- DATRON Play Button allows direct program start from the work area, enabling fast and convenient operation without returning to the control terminal

- Wired barcode scanner ensures accurate recognition of all standard 1D, stacked, and 2D codes for efficient job and data handling

-

Fill Level Monitoring

- Intelligent fill level monitoring tracks cartridge material levels in real time to prevent unexpected runouts

- Customisable warnings and piston position detection ensure smooth, uninterrupted dispensing and improved process reliability

Watch the DATRON evo600 in Action

Explore Other DATRON Machines

-

DATRON neo

DATRON neoThe DATRON neo is ideal for small to medium-sized parts, prototyping, low-volume production, R&D and education applications and space-constrained environments.

-

DATRON M8Cube

DATRON M8CubeThe DATRON M8Cube is the best selection for economical machining of housings, extrusions, and front panels of aluminium and other non-ferrous materials.

-

DATRON MLCube

DATRON MLCubeThe DATRON MLCube is the ideal solution for cost-effective sheet machining and large component production, including front panels, housings, and other aluminium workpieces milled in nested form.

-

DATRON MXCube

DATRON MXCubeThe DATRON MXCube is a high-capacity, high-precision machine for high-volume production. It's optimised for heavy material removal and delivers outstanding stability, accuracy, and dynamic performance.